What are the Similarities and Differences between Lean and Six Sigma?

There are a lot of different process improvement programs on the market today and everyone has their favorite. I am sure you recognize a few of these programs. Have you ever wondered what the difference is between each of these? There are many consultants in the market that are advocating the use of one of these improvement methods to solve all of your organizational problems. But will all of these work in any situation? Or, are there specific situations that are better suited for a particular approach?

Common Process Improvement Programs

- Six Sigma

- Lean Thinking

- Theory of Constraints (TOC)

- ISO 9000 Quality Standards

- Total Quality Management (TQM)

- Toyota Production System (TPS)

- Just-In-Time (JIT)

- Benchmarking

We will explore the advantages and disadvantages of each one and the best way to use each method to realize improvement.

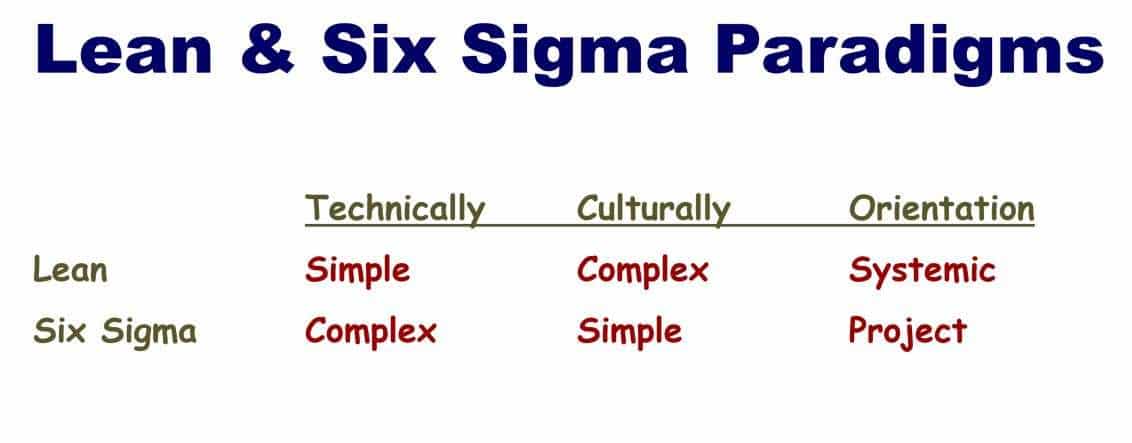

Lean and Six Sigma: Similarities and Differences

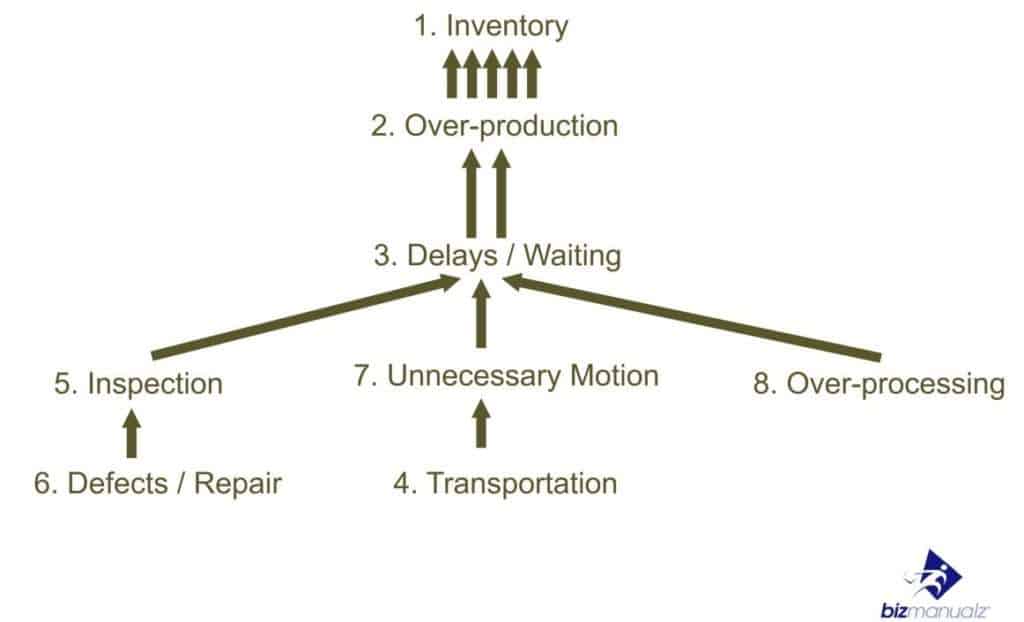

Lean and Six Sigma have many similarities and differences. If you see waste happening, you can eliminate it. A lean visual factory helps us to remove obvious waste. Takt times help us to balance lines, while standard work, total preventive maintenance, and 5S help us reduce variation.

Lean is not really a set of tools, it’s about culture, the work environment, and a way of thinking. Lean is based on thinking about waste or what does not make money in your business like unsold inventory, product defects, delays, or unnecessary actions. If you see waste STOP and fix it. That’s lean. If you make the waste obvious then works will see it. Once everyone begins to see all of the waste around them, they can start to fix it.

Lean works well at the beginning of any quality program, where you want to sensitize the company to waste and teach continual improvement. Lean is fast, agile, and prepares people for change. Its also simple to teach workers to see waste.

Six Sigma presents a structured way of looking at process variance to help your employees get over intractable problems. If you are blessed with a high transaction environment and can easily recognize defect data and trends, you can eliminate the defects. Statistical process control helps us to remove obvious control limit violations, detect instability, and monitor process drift by separating the core process from the process noise or what is getting in the way of the process.

Six Sigma uses DMAIC, DOE, and DFSS to help us to filter out noise to methodically remove less obvious waste, which allows us to focus on the vital data hidden within the noise. Six Sigma works well in the middle of any quality program, where you want to move the company to higher (i.e., world-class) levels of performance. Six Sigma is sophisticated, technical, and harder to implement although it can help to remove performance obstacles.

Six Sigma uses DMAIC, DOE, and DFSS to help us to filter out noise to methodically remove less obvious waste, which allows us to focus on the vital data hidden within the noise. Six Sigma works well in the middle of any quality program, where you want to move the company to higher (i.e., world-class) levels of performance. Six Sigma is sophisticated, technical, and harder to implement although it can help to remove performance obstacles.

Both Lean and Six Sigma require discipline, time, and a subject matter expert to deploy and manage. Neither requires a lot of money relative to the cost of poor quality they reduce. Each can eliminate obvious waste and reduce variation, though what is considered obvious or a variation may differ in each program.

Lean and Six Sigma by themselves can play a valuable role in any continuous improvement program, but it’s when they’re used in combination that companies will see the biggest, longest lasting payoffs.

WHEN DO YOU USE LEAN?

Lean thinking can be used to reduce obvious waste. What waste is obvious? There are eight common wastes that are the most obvious and, therefore, are the easiest to remove from your system. These are the “low hanging fruit” on your quality tree. Lean can be rolled out relatively easily and implemented company-wide.

Lean is a good starting point for companies looking to build a new quality system. Lean is fast — small projects can be completed in days, or even hours. Most Lean projects require little investment beyond people to implement the project. You can use your regular employees on the project, giving them a little bit of Lean training to get started.

Six Sigma

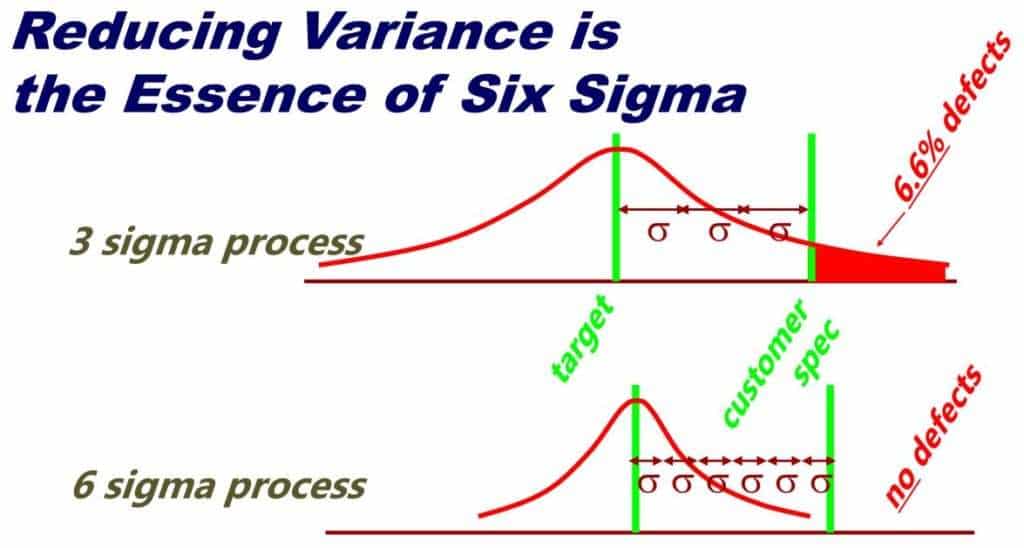

In statistics, a ‘sigma’ (s) refers to the standard deviation from the mean of a population. Standard deviation describes the likelihood of your next data point deviating from the mean of the whole data set. The sixth sigma refers to the likelihood that only 3.4 out of every 1 million data points will appear outside the sixth standard deviation. That translates into less than 4 errors per million transactions.

Six sigma is one of the process improvement programs that is all about variance reduction. What do we mean by variance? We are talking about the amount of control you have over your processes. Another way to look at it is how good you are at predicting or forecasting the future outcomes of a given process.

For example, if we are talking about an accounts receivable process with a goal (effectiveness criteria) of collecting all receivables within 30 days, then we would measure the time variance of each individual receivable collected against the average days outstanding (let’s say it’s 35 days) for the whole population of receivables collected. If your individual collections range from 25-90 days then we would say your process variance is high, which translates into a low sigma. The difference between the process average (35) and the goal (30) would reflect your process’ capability or your process’ ability to meet the target.

As we have seen in business metrics for results, variance is a symptom of waste. So, the higher the sigma, the greater the control you have over your process, which means greater forecasting accuracy and less error. Processes that exhibit a lot of variance mean they have a lot of waste.

The name six sigma tells us a lot about this one of the process improvement programs. You can see that the six sigma approach involves a little advanced math, some statistical tools to understand the various fluctuations of a process, and a lot of data to run the calculations.

DMAIC

Six Sigma is best for problems where the solution is not obvious. Six Sigma is a five-step process model called DMAIC:

- Design,

- Measure,

- Analyze,

- Improve, and

- Control.

Six sigma is very problem focused. It uses a scientific approach called DMAIC to analyze a specific problem. DMAIC stands for Define, Measure, Analyze, Improve and Control, which is also known as the learning loop or PDCA.

Process improvement programs like Six sigma are ideal for scientific or numbers based organizations including: high technology manufacturing (semiconductors), high transaction businesses (check or postal processing), fast paced research and development (electronics, pharmaceuticals), or environments where errors are extremely expensive (surgical operations, space exploration, aircraft takeoff and landings).

Motorola and General Electric are two high technology companies that have helped to popularize the six sigma concepts. Motorola developed the methods back in the 1980’s to improve manufacturing yields. However this method is not ideal for low transaction situations (most small businesses) or mature industries with simple manufacturing processes (like baking).

Six sigma requires a rigorous application of DMAIC and statistics that may not be suited to many organizations. It is also highly problem focused, which works well for big problems but can lead to sub-optimization when applied across an entire organization. That is one department or process being optimized at the expense of another.

A lot of process improvement programs are available on the market today. If you are in a high technology, high transaction, or expensive error environment then six sigma will work real well for your organization. If not, then perhaps Lean Thinking (waste reduction) or the Theory of Constraints (throughput improvement) would work better.

WHEN DO YOU USE SIX SIGMA?

The DMAIC model is how scientists solve problems. They collect data, apply statistical analysis, and isolate the problem. Then, they analyze the data until they find correlations, test possible solutions, and solve the problem.

Some Six Sigma projects can take as few as three months, while others require 12 months or more to complete. Six Sigma requires technical experts (“black belts“) trained in the tools, statistics, and solving problems. Six Sigma works best on isolated problems and can take years to implement company-wide.

Lean can be used at any point in time but is, perhaps, best used to implement a quality culture of continuous improvement. Lean is a great starting point for building a quality system, since it’s easy to get started, projects are quick, and results can be obtained fast.

Six Sigma is better after a quality program is under way and employees have become accustomed to improvement. Six Sigma is better at large-scale, expensive problems that you can collect a lot of data around. Six Sigma is a mature quality approach that requires discipline, trained individuals, and big problems.

You can start with Lean and build an improvement culture. Then, after years of Lean training, implementing lean projects, and resolving the more obvious wastes in your organization, you’ll be ready for a more mature program like Six Sigma. Some have now started to call this “Lean and Six Sigma”.

It needn’t be a case of “either…or”. Instead, it may be a case of the whole being greater than the sum of the parts. Lean and Six Sigma, apart from one another, are very good quality improvement tools. Together, Lean and Six Sigma are great!

Hi I hope you are doing well and in good health

Thanks for your e mail

Pls can you explains for me how we use the six sigma in

drug design in case study

Best regard

Basil

Thanks for the comment, it is greatly appreciated. Well-written and insightful.

I will more than gladly take you up on that offer for a meal and wine if you are ever on this side of the planet 🙂

Totally agree, very similar to my recent Blog post – ( http://www.sixsigmaindubai.org/six-sigma-dubai/six-sigma-certification-dubai/ )

Good discussion. Thank you.

That’s a great post about when to use Six Sigma. Do you mind if I am using it as a reference on my website?

Thanks for visiting. Yes please reference our site. Good luck.