How to Improve Process Control with Six Sigma Tools

Aiming for perfection is a pretty lofty concept. It’s definitely not easy, especially when you’re speaking of core business processes. Moving toward perfection requires measurement, analysis, and documentation. If you really want perfection, or the closest thing to it, you need sophisticated tools, like Six Sigma tools. But…is driving toward perfection worth the effort? This article is about how to improve process control with six sigma tools.

Improve Process Control with Six Sigma Tools

If you want to increase quality and dramatically save costs in production, then, yes — the road to perfection is definitely worth the driving time.

Let’s look at how Six Sigma tools can decrease variability and increase quality in your processes.

Six Sigma DMAIC

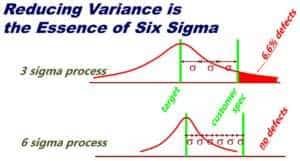

The Six Sigma methodology (DMAIC or Define, Measure, Analyze, Improve, Control) is an advanced set of tools designed for problem-solving and quality improvement. A ‘sigma’ refers to the standard deviation from the mean of a population. Standard deviation indicates the likelihood that your next data point will deviate from the mean of the data set.

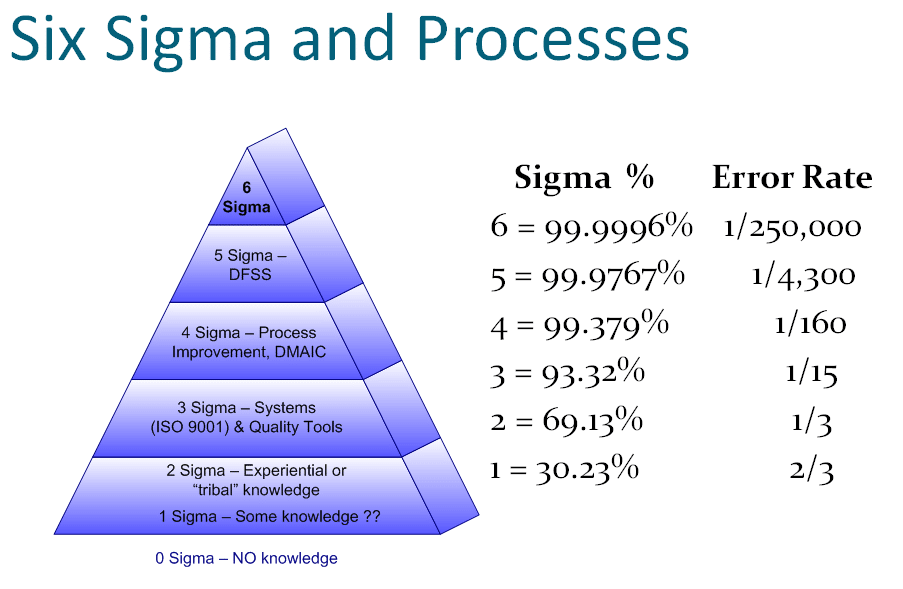

At the bottom of the Six Sigma pyramid begins a system’s current process capability. Usually at 1 or 2 Sigma levels is “tribal” knowledge based on first-time experiences. An organization moves up the pyramid to 3 Sigma as systems are put in place. To hit 4 Sigma, statistics and modeling tools are used for significant process improvement. And, finally, to aim for that near perfection, organizations apply DFSS, or Design for Six Sigma.

Why?

Six Sigma and Error Rate

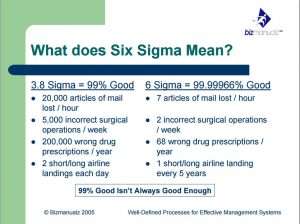

Why do organizations — and why should yours — use these concepts to move up the pyramid and toward quality improvement? Why is it necessary to measure, analyze, and document processes and, if needed, make those desired changes? Why drive toward perfection, and what does it mean in real terms?

If your current error rate runs at 1 Sigma, then that effectively means you have two defects (unusable products) out of every 3 parts. That means 67% of your costs simply become waste, with no return on your investment. At 2 Sigma, quality improves with 1 out of 3 parts as defects. But that still has an error rate of 33%. Not until 3 and then 4 Sigma levels will you see dramatic improvements. Put in these terms, you quickly see how such errors keep you from realizing a greater potential.

Six Sigma Methodology

Organizations most effectively utilize Six Sigma methodology in two situations. One, if a business works with a very high volume of transactions per year, then they can not tolerate low sigma levels. For example, a 99% effective rate for 1 billion transactions per year still yields 10 million defects. In any industry, that is not acceptable.

Rolled Throughput Yield

Another situation that calls for Six Sigma methodology is when an organization (i.e. manufacturing) has critical processes with multiple steps. Here total error rate is critical. For example, the Rolled Throughput Yield or effective rate is 95% for each step; however, that does NOT give the total error rate as 5%. You must take the 95% for the first step and multiply it by 95% for the second step, the third step, and so on. With a great number of steps (let’s say five steps), your total effective rate could significantly decrease (77.4%). So, to avoid high volatility, this organization can not tolerate low sigma levels.

95% = 95.0%

95% x 95% = 92.5%

95% x 95% x 95% = 85.7%

95% x 95% x 95% x 95% = 81.5%

95% x 95% x 95% x 95% x 95% = 77.4%

Organizations can also determine error rate by effectively reversing the typical process of Six Sigma. You can calculate the mean and variance in your process to define the error rate. This tells you where you are currently on the Six Sigma curve. For example, if your calculation tells you that you’re on a 1 or 2 sigma level, then this is an area in need of improvement. This gives you an opportunity to look at the data more carefully, take the mean and variance of each step of the process, and determine in which step the process is having problems. Or it could tell if you there are many steps causing the problems and, thus, the cumulative increase in error rate.

Strong Processes and Procedures

Organizations use the Six Sigma methodology, because you can’t get any higher than 2 Sigma (“tribal” or basic knowledge) without putting strong processes and procedures in place. And without strong processes and procedures, you can not move toward higher quality and system optimization – toward perfection. Are you really satisfied with 67% of your product lost as waste? Are you satisfied with such high variability in your system?

If needed, you can change your process to reduce or eliminate this variability or error. Six Sigma methodology tells you when to take action to solve a problem. It moves an organization to consistently meet the requirements and minimize the resources used in its management system. And it creates the desired results for which the system was designed.

Policies and Procedures Systems

Remember, though, you can only get to 3 or 4 sigma by developing a system of policies and procedures for measurement, analysis and documentation of your processes. And with this you will easily see that reducing your error rate and moving toward perfection with Six Sigma tools is well worth the driving time – and, more, crucial to your system’s control.

Leave a Reply