Make Your Business Lean

Are you struggling with optimizing your manufacturing processes? Look no further. In this article, we will explore the importance of COO optimization and provide practical tips to help your business achieve manufacturing process optimization. Say goodbye to inefficiencies and hello to improved productivity and profitability. COO Optimization Achieving Manufacturing Process Optimization.

Read moreWelcome to the world of operational excellence, where efficiency and effectiveness reign supreme. As a COO, you know the importance of streamlining processes and maximizing resources. But with competition and market demands constantly evolving, staying ahead can be a challenge. That’s why we’ve created the ultimate guide to help you achieve operational excellence for your organization. […]

Read moreDear readers, are you struggling with managing operations for your business? If so, this article is for you. As competition continues to increase, it’s crucial to have efficient and effective operations in order to stay competitive. In this article, we will dive into the COO Lean Operating Principles and how they can help streamline and […]

Read moreWelcome to the world of COOs, where operational efficiency is crucial for business success. But with so many methodologies and frameworks, how do you know which one is right for your organization? In this article, we will explore the benefits of Lean Six Sigma and why it’s essential for COOs to understand its principles and practices. […]

Read moreDear Reader, Are you a COO looking to improve the efficiency and productivity of your organization? Look no further. In today’s fast-paced and competitive business world, it is essential for COOs to understand and implement Kaizen principles to stay ahead of the game. This article will provide valuable insights and tips for COOs to incorporate Kaizen […]

Read moreContinuous process improvement is essential for success in today’s business world. As a COO, it’s important to comprehend the fundamentals of this concept. This article highlights what you need to know to drive growth and efficiency. What should a COO Know about Continuous Process Improvement?

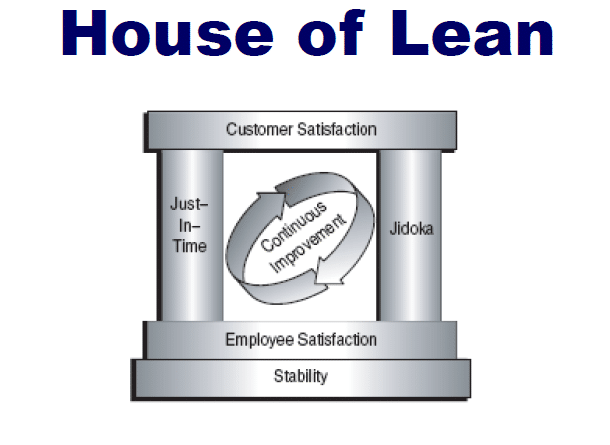

Read moreThe COO of Lean Manufacturing is like a referee in a game of tug-of-war between efficiency and chaos. It involves practices to eliminate waste and increase efficiency in manufacturing processes. Recent years have seen the growing importance of such practices. What should a COO know about lean manufacturing principles?

Read moreValue stream mapping is a really important tool for COOs. It helps them to see how their organization works, spot areas of waste, and decide how to improve. Creating a map of the value stream gives COOs insights into their business. They can use this to see where they can cut waste, reduce wait times, and […]

Read moreLean is a journey. If you’re like most companies, your lean journey starts in manufacturing with something simple like a 5-S program and then moves on to more difficult lean tools like analyzing your value streams and then eventually reorganizing your whole supply chain. This is all great stuff but when are you done? What […]

Read more