How to Meet Quality Standards with ISO 9001

In today’s hectic business environment, it is vital that every employee is on the same page, right? But how do we know if we meet quality standards?

How to Meet Quality Standards

Business owners and executives can avoid the uncertainty, and that’s where ISO 9001 certification comes in.

What does ISO stand for?

First, it is not an acronym. It is based on the Greek word (isos), which means equal. The ISO organization was created to equalize trade between countries by coming up with standards for just about everything…

The ISO, or International Organization for Standardization, was established in 1947 to develop international standards for everything from electronics to management systems. Having over 20,000 standards currently in place, ISO has created the Quality Management System (QMS) standard known as ISO 9001. This began the drive toward quality standards.

What are quality standards?

ISO 9000 is a group of guidelines and standards (ISO 9001) originally designed (BSI 1987) to set management system requirements for businesses. It has since been revised roughly every seven years in 1994, 2000, 2008, and 2015. I suspect the next one will come out in 2022.

There are many other quality standards in other sectors like IATF 16949 in automotive, AS9100 in aerospace, ISO 13485 for medical devices, and ISO 22000 for Food Safety, just to name a few.

Why Develop Quality Standards?

Quality standards are developed to assist organizations to improve customer satisfaction, enhance company performance, develop best practices. build stable process, collect QMS feedback,

Improve Customer Satisfaction

Companies choose to implement ISO 9001 and get certified because many customers and industries require it. By keeping customers happy, they can increase sales and profitability for their business, and meet quality standards. And if an area of the company’s program appears to be too bureaucratic and non-value-adding, then it might also be an area for continuous improvement efforts.

The idea is to Improve your consistency, customer satisfaction, and competitive advantage over time.

Enhance Company Performance

Both customers and industries alike use ISO certification as a way to evaluate and audit their suppliers and products. Through an independent verification process, customers can gain assurance of their suppliers’ products. And as a supplier becomes certified, the testing requirement is waved, which saves the company both time and money. This can reduce your Cost Of Quality (COQ).

ISO 9001 is based on the idea of effectiveness, that your organization continually improves at achieving desired results.

Develop Best Practices

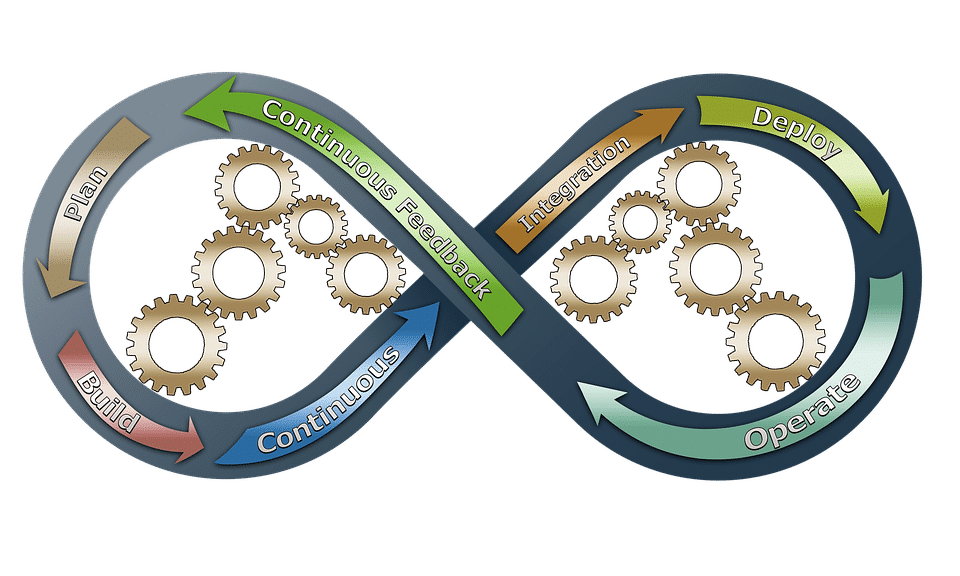

Employed as a “Best Practices” model, the latest ISO 9001:2015 utilizes the philosophy of the “Plan-Do-Check-Act” continuous improvement cycle to achieve requirements. This process approach centers around eight quality management principles used by management as a guide toward improving performance and identifying the main elements needed in a good quality system:

Customer Focus

Customer Focus- Leadership

- Engagement of People

- Process Approach

- Improvement

- Evidence Based Decision-Making

- Relationship Management

Build Stable Processes

ISO 9001 policies, procedures and forms can provide employers, managers and employees with a systematic and consistent approach to implementing policies, plans, procedures and work routines. Instead of building their own policies and procedures from scratch, some companies prefer to hire professional writers that have already prepared a set of written policies and procedures to help on the way to certification.

Collect QMS Feedback

In the certification process, an independent registrar will perform an on-site audit of a company’s operations to verify that it complies with the ISO standard, or that you meet quality standards. If the business complies, then that company will be registered as ISO 9001 compliant. This ensures organizations receive feedback on their QMS.

Meet Company and Customer Needs

On the way to certification, a business can meet its ISO needs by:

- Using well-defined processes and procedures to build stable processes

- Training in the audit and certification process

- Continuously improving with ISO 9001 standards

Notice the Difference

With complete procedures manuals for ISO 9001 Quality Management System, required HR procedures, and an ISO training class, a template like an ISO 9001 2015 Procedures can help a business on its way to ISO 9001 certification. Sometimes the effort can be very great, but companies typically notice a remarkable difference in efficiency and effectiveness after the first year.

Developing best practices is a great way to implement ISO 9001 standards along with your company values. It’s important to know that if you haven’t used these best practices before, it may be difficult to make them a priority. I would recommend bringing in a consultant to help you make these best practices specifically relevant to your business to help them take hold easier.

The ISO, or International Organization for Standardization, was established in 1947 ?????!!!!!!

Is it true???

To my knowledge there was standard in 1987(BSxxxx) considered as the first ISO std ???

The first Quality standard was not the first ISO standard. British Standards Institute (BSI) was used as the basis for ISO 9001, but there were many other standards in use by then, other than Quality.