Why is Consistent Quality Important?

Customers demand consistency and quality — they need it to make informed purchase decisions. Why is Consistent Quality Important? Learn why consistent quality is important to the future of your business.

What Is the Relationship Between Consistency and Quality?

For example: Let’s say you run a restaurant. At your restaurant, you have a different chef every day. Each chef makes the menu according to their preferences.

If your menu changes every day — if there’s a high degree of variability in processes — a lot of customers will be put off. Some people like variety and go out of their way for it, but most of us are creatures of habit.

We find something we like and we stick with it; we go where we know what we’re getting. If we don’t know what to expect from you, you may not be in business for long. This is but one example of quality.

What Does Consistency and Quality Entail?

Well, consistency with quality means value, and value means happy customers. Happy customers will return, and they’ll tell their friends. who will tell their friends, and they’ll grow your business.

Are Consistency and Quality the Same?

Not necessarily. You can make a consistently bad product, which obviously isn’t good for your business. You need to make a consistently good product, which ISO 9001 — specifically, a quality management system designed around the ISO 9001 quality standard — can help you produce.

Excessive Variation Harms Your Business

If yours is like most companies in difficult times like these, you may struggle to achieve consistency in remote and in-house processes. Every employee reacts to their own problems and can’t be bothered with others. Furthermore, no one has the time or “luxury” to look ahead, let alone ensure consistency in the here-and-now. The result is a decline in quality, revenues, morale, and…the number of employees.

It’s generally not good business to let your employees make your products any way they want, whether your product is hamburgers, tires, or remote data backup. Too much variation, or inconsistency, in your product will hurt your business. But there are methods for dealing with variation.

Reducing Variation with Lean Six Sigma

You can do something about this! Work towards improving consistency in your work first. Good management looks ahead, plans for the future, defines the “product”, and develops measurable objectives, active job descriptions, and clearly defined policies and procedures.

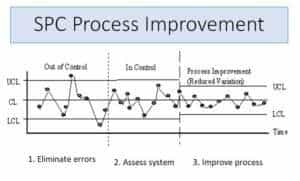

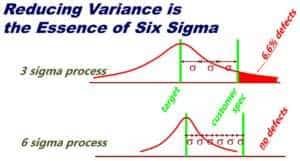

Many companies use Lean and Six Sigma process improvement methodologies to address variability in processes. In fact, reducing variation is the essence of Six Sigma. Your organization can learn to improve process control with Six Sigma tools. Process control is how you achieve a stable, consistent process with reliable quality. Business procedures provides the standards for work to sustain control over your processes.

The Relationship Between Consistency and Quality

Quality management works toward delivering a consistent product, inside and out. Unless everyone in your business is doing everything they can to deliver a consistent product internally, you won’t see consistency in your finished products.

Developing procedures and instituting management by procedures will help your organization develop consistency and quality will follow. Be a leader and deliver consistent products consistently. If you deliver high quality consistently, everything else takes care of itself.

This is good information – thanks for sharing

[…] Anderson, C. (2017). Consistency and Quality. Retrieved from Bizmanuals: ; […]