How Do You Create ISO 9001 Procedures for a QMS?

How useful is your Quality Management System (QMS) if the ISO 9001 Procedures Manual is a burdensome book, with tons of detail, but little real value? How do you create ISO 9001 procedures for a QMS?

ISO 9001 Procedures

The old ISO 9001 Quality standard required six ISO 9001 procedures: Document Control, Record Control, Control of Nonconforming Product, Corrective Action, Internal Audit, and Preventive Action. That was the minimum requirement, but even the leanest of Quality Management Systems will probably need a few additional procedures.

Understand the New ISO Requirements

The latest ISO 9001 2105 standard requires NO Quality Procedures. None. Zip. Nada. You don’t need to have any quality procedures at all. How is this possible? There is a documented information clause 7.5.3 that requires documented information (documents and records that you decide are needed) be controlled, but nowhere in the standard does it say you must have a procedure for anything. You don’t even need a Quality Manual.

Other Quality Management System (QMS) procedures may be needed to bring emphasis, consistency, and control to a company’s core business and processes and what you consider “Critical To Quality” (CTQ), but that is entirely up to your organization and not required by the ISO 9001 standard. So for a very Lean QMS there could be six to ten system procedures.

Before we discuss how to make the individual procedures more Lean; how about a story?

ISO 9001 Procedures Out of Control: A Case Study

I audited a small manufacturing company in central Illinois who was a supplier for a large defense contractor (which I represented). It was a privately owned company of about 80 employees with the owner as President.

This company had been ISO 9001 registered to the old 2008 standard for about six years. After the Audit Opening Meeting and facility tour, I started the audit by checking system procedures they reported that they were still using.

The Quality Manager indicated that there were two sets of procedures, one set in administration and one set on the shop floor. “Well, let’s go check the set on the shop floor,” I told him.

We arrived at a table that had a “procedure manual” that was about six feet long. It had a heavy, solid support on each end with three rods running between the supports where standard holes were punched in 8 1/2 x 11 sheets of paper.

Pages were placed back to back, and then inserted into a plastic page protector. The page protector was then inserted into the “procedure manual.”

The Quality Manager proudly explained that as they added more procedures they could just add additional sections of the three rods to expand, thereby moving the support ends farther apart. Get the picture?

I quickly noticed that Procedures, Work Instructions, Part Drawings, as well as all kinds of other documents were included into this “procedure manual.” What they had were actually work instructions, but they called everything a procedure.

If you think it is critical to quality, and you write documented information for it, then the ISO standard says you must control it. Ask yourself if it is really critical to quality. If not, eliminate it.

I asked the Quality Manager to show me the Documented Information Procedure. After some searching he could not find it! He told me he was sure it was there somewhere.

Next I asked him for the Internal Audit Procedure. He could not find that! Corrective Action? You guessed it.

I asked him if there was any specific procedure that he cared to show me. His response was, “Well, if there was I probably could not find it either.” I did ask him if he understood that the procedures I had requested were specified in his quality manual. He said that he did.

ISO 9001 Procedures Manual

We moved to the ISO 9001 procedures manual in the administration area and I asked if there was someone else who might be able to find these required procedures. He returned with his assistant and informed me that she had been with the company for several years more than his two with the company.

After some searching, the assistant could not find the requested procedures in the administration area “procedure manual” either. It wasn’t looking very good for this auditee, and it was only 10:00 in the morning.

Follow-up discussions revealed that they constructed their ISO 9001 procedures manual under the premise that ISO 9001 requires everything to be documented. They thought their “procedure manual” was what the ISO 9001 Registration Auditor was looking for.

Since they had not received any non-conformances to their QMS in six years, they assumed that they were doing the right thing. The fact was, however, that I could not find a single person in the company that used the ISO 9001 procedures manual.

The belief of the company was that they had to have all those “useless” procedures because that is what ISO required, and they had to do ISO because it was what their customer’s required. This company had some serious issues with their QMS.

Not only did they have specific compliance issues to the ISO 9001 Standard, they had a system that did not provide any real value. They did not know how to use their Quality System, and they did not understand ISO 9001. Their most consistent response to me was, “Well, our ISO Auditor did not have a problem with that.”

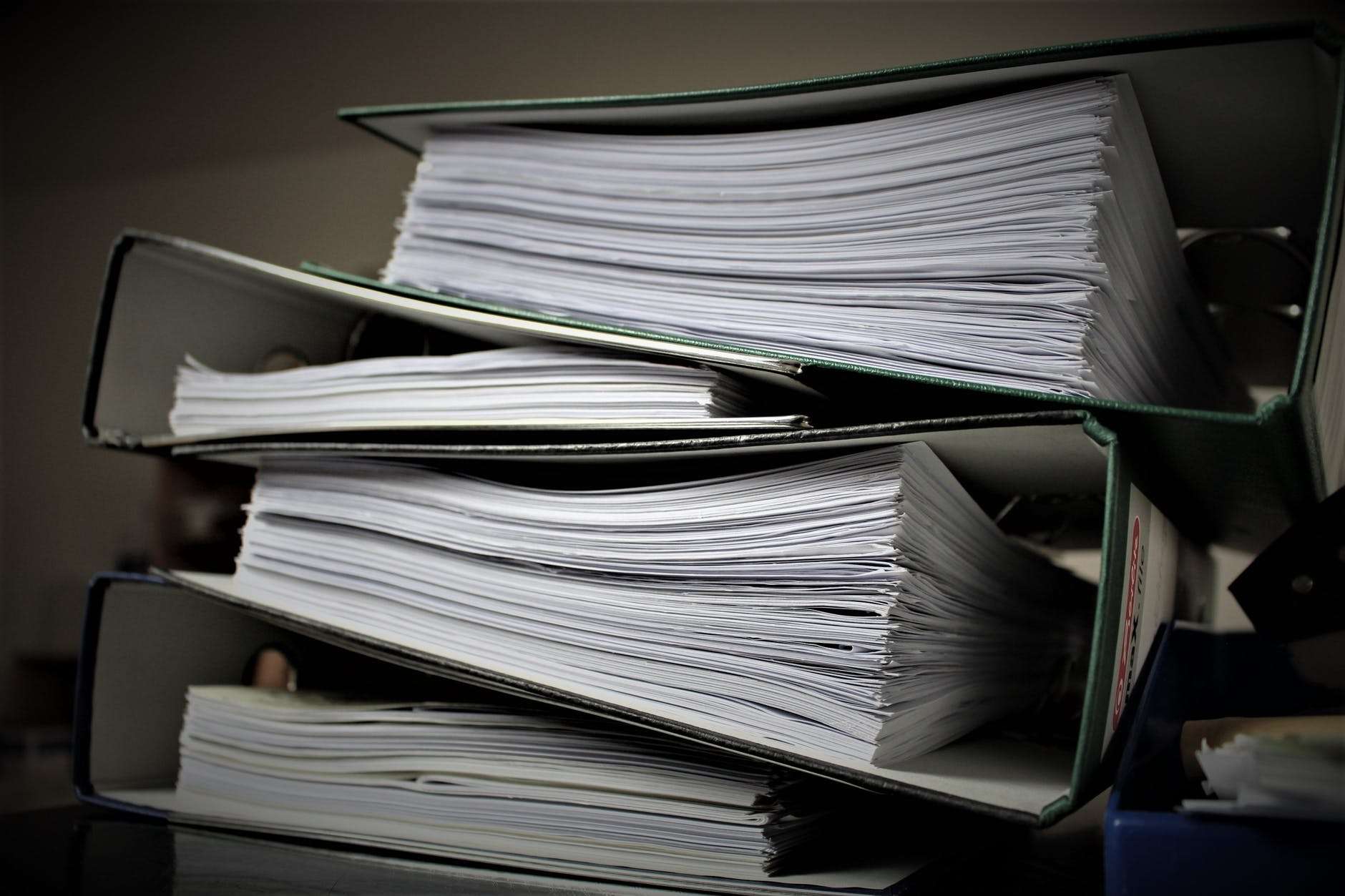

Where is Your QMS Binder?

That was definitely one of the largest binders that I’ve ever seen. Imagine, though, if the company had understood that ISO 9001

excellence does not come from lots and lots of procedures. What if they had grasped the concept of focusing on processes and had only six to ten ISO 9001 procedures?

What if they had thought about providing value to the employees by issuing Work Instructions at the point of use? One thing is for sure; I would not have written nearly as many non-conformances to their QMS.

Lean ISO 9001 Procedures

This story is a great illustration of what is not lean–how “less is more.” Fewer ISO 9001 procedures can actually provide more value to the QMS.

The same concept also applies to the length of each procedure. The starting point should be to address the minimum ISO 9001 requirements for procedures, and then build on the system as needed for the benefit of your organization. Long procedures may not benefit anyone that has to use them.

The ISO 9001 Standard does not specify or prescribe a format for procedures, nor does it specify a length. All an organization has to do is to meet the requirements given in the standard. Since no one wants to read a procedure “book” or page after page of procedure text, why write them?

Shorter ISO 9001 Procedures

When you use our online document management system, procedures, records, and rights to use or edit them are managed within the web-based system. Deployment — and control — become very easy.

Why not write one, two or three page procedures? Why not use flow charts or process diagrams? Eliminate lengthy text in paragraph format – no one wants to read it anyway. The information is brief and easy to understand if you use flow charts, process maps, numbered lists, etc.

A Documented Information procedure for ISO 9001 can be done in two or three pages using a flow chart, a document list, an approval block, and allow for revision history. The Records Control procedure is now considered documented information too.

The Internal Audit, Control of Nonconforming Product, Corrective and Preventive Action Procedures can all be simple two page documents or not even included at all. They are not required anymore.

ISO 9001 Procedures for a QMS

Try it! Change your paradigm and your organizational approach to Lean ISO 9001 Procedures. This will reduce cost and you will see for yourself how easy it can be to follow and use System Procedures. You may be surprised that people will actually use the procedures.

Leave a Reply