Who Are the Top Quality Gurus?

Many prominent Quality Gurus have emerged within the quality field, but some have stood out as key figures of quality. Most have passed away, but their memory still lives on in the ideas, concepts, and methods that permeate our quality thinking today. Who are the top quality gurus?

Top Quality Gurus

In today’s competitive world, ensuring high-quality products and services has become paramount for organizations across industries. This pursuit of excellence owes much of its success to the contributions of visionary individuals known as quality gurus.

These eminent figures, through their groundbreaking philosophies and methodologies, have revolutionized the field of quality control and assurance. In this article, we will explore the accomplishments and significant discoveries of some of the most influential quality gurus, whose legacies continue to shape the modern quality management landscape.

Listed below are the Top Ten Quality Gurus who have shaped quality as we know it today.

1. Dr. Walter Shewhart

First of the Top Ten Quality Gurus is Dr. Walter Shewhart who developed the Plan, Do, Check, Act (PDCA) cycle (known as “Plan-Do-Study-Act” in some circles) as well as theories of process control and the Shewhart transformation process. He is considered the father of statistical quality control (SPC) and Shewhart cycle (PDCA).

2. Dr. W. Edwards Deming

Regarded as the father of the quality revolution, W. Edwards Deming emphasized the importance of statistical analysis and process improvement. His pioneering ideas transformed the way organizations approached quality control.

Deming introduced the concept of Total Quality Management (TQM) and the Deming Cycle, also known as the Plan-Do-Study-Act (PDSA) cycle. He believed in a systematic approach to quality improvement and highlighted the significance of employee involvement. Deming’s teachings played a pivotal role in Japan’s post-World War II economic resurgence.

Dr. Deming developed a complete philosophy of management, which he encapsulated into his “fourteen points” and the “seven deadly diseases of management”. He advanced the state of quality, originally based on work done by Shewhart with his explanations of variation, use of control charts, and his theories on knowledge, psychology and variation. Deming greatly helped to focus the responsibility of quality on management.

3. Dr. Joseph M. Juran

Dr. Joseph M. Juran is renowned for his contributions to quality management, particularly in the field of quality planning and quality improvement. Dr. Juran advocated the idea that quality does not happen by chance; it must be planned and managed. Dr. Juran emphasized the need for organizations to focus on customer satisfaction and the importance of a structured approach to quality management.

He developed the quality trilogy – quality planning, quality improvement, and quality control. Quality assurance policy statement and procedures quality improvements that raise the level of performance, which then must be controlled or sustained at that level in order to start the cycle again.

4. Dr. Armand V. Feigenbaum

Dr. Feigenbaum developed the idea of total quality control based on three steps to quality consisting of quality leadership, modern quality technology, and an organizational commitment to quality. As well as the idea of the hidden plant or factory.

5. Dr. Kaoru Ishikawa

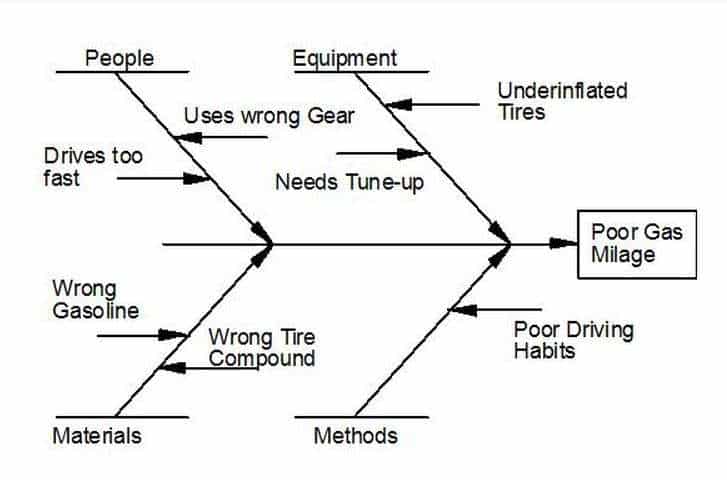

Dr. Ishikawa made significant strides in advancing the field of quality assurance, particularly in the realm of quality control through statistical tools. He developed the Ishikawa diagram, also known as the fishbone or cause-effect diagram. , which is widely used for identifying and analyzing the root causes of problems. Ishikawa’s work popularized the use of statistical process control (SPC) and provided a systematic approach to quality problem-solving. He also emphasized the importance of employee involvement and promoted the concept of quality circles. He was known for popularizing the seven basic tools of quality and the philosophy of total quality and the internal customer.

Ishikawa’s work popularized the use of statistical process control (SPC) and provided a systematic approach to quality problem-solving. He also emphasized the importance of employee involvement and promoted the concept of quality circles. He was known for popularizing the seven basic tools of quality and the philosophy of total quality and the internal customer.

6. Dr. Genichi Taguchi

Dr. Taguchi developed the “Taguchi methodology” of robust design, which focused on making the design less sensitive to variation in the manufacturing process, instead of trying to control manufacturing variation. This idea of “designing in quality” has become an important tenant of six sigma today.

Taguchi’s approach emphasized robust design, which aimed to minimize the effects of variation on product performance. He used Design of Experiments (DOE) and introduced concepts such as Taguchi Loss Function, which quantified the economic losses resulting from deviations from the target value. Taguchi’s methods provided a framework for reducing variability and improving product quality during the design stage.

7. Dr. Shigeo Shingo

Shigeo Shingo developed lean concepts such as Single Minute Exchange of Die (SMED) or reduced set-up times instead of increased batch sizes, as well as Poka-Yoke (mistake proofing) to eliminate obvious opportunities for mistakes. He also worked with Taiichi Ohno to refine Just-In-Time (JIT) manufacturing into an integrated manufacturing strategy, which is widely used to define the lean manufacturing used in the Toyota production system (TPS).

8. Dr. Philip B. Crosby

Dr. Philip B. Crosby was the quality guru that developed the idea of Cost of Poor Quality (COPQ) to explain how “quality is free”. He believed implementing quality improvement pays for itself through the savings from the improvement, increased revenue from greater customer satisfaction, and the improved competitive advantage that results.

He popularized “zero defects” to define the goal of a quality program as the elimination of all defects and not the reduction of defects to an acceptable quality level, which challenged organizations to strive for error-free performance. He emphasized the importance of prevention rather than detection of defects and

Dr. Crosby believed that quality is free and that the costs associated with poor quality outweigh the investments required for prevention. His philosophy paved the way for a cultural shift within organizations, fostering a commitment to continuous improvement with a zero tolerance for defects.

9. Dr. Eliyahu M. Goldratt

Dr. Goldratt developed the Theory of Constraints which focuses on a single element in a process chain as having the greatest leverage for improvement (i.e., “1% can have a 99% impact”). This compares to the Pareto principle which states that 20% of the factors have an 80% effect on the process.

10. Taiichi Ohno

Last of the Top Ten Quality Gurus we will discuss is Taiichi Ohno. He developed the seven wastes (muda), which are used in lean to describe non-value-added activity. He developed various manufacturing improvements with Shigeo Shingo that evolved into the Toyota Production System.

Quality Gurus

The field of quality control and assurance owes much of its advancement to the pioneering work of these quality gurus. From statistical analysis and systematic improvement approaches to preventive strategies and customer-centric philosophies, their contributions have shaped modern quality management practices.

Quality gurus like Dr. Deming guided organizations worldwide to achieve excellence, maximize customer satisfaction, and drive continuous improvement. As we continue to evolve, it is essential to honor the legacy of these quality gurus and build upon their invaluable insights to create a future where quality is a foundation for success.

Its nice and valuable information was gifted from all the quality guru. This info is useful for development of process, minimize the series and improving the quality of product.

Great Article on Quality Gurus. Deming’s approach had more people and people development focus like working together, importance of training people on the job, importance of leadership etc. while other Quality Gurus have focused more on Quality, defects, the systems per se. At the end of the day, people need to drive the systems and make things happen in the organization.

What About Shainin and Ronald A Fischer

Excellent summarized facts

Mostly agree with you, these are all pioneers in quality management and deserved a summary/writeup, complements from KC @ProSigmaIndia

It is a wonderful artical about Quality Gurus

Quality Circles are attributed to ISHIKAWA the great.

I think Shigeo Shingo is overrated and took personal credit for concepts like SMED that were already in development at Toyota when he came there to teach and consult. What he did do was capture the essence of TPS and publicize it.

Well, sounds similar to the case of Edison and Tesla right? or the McDonald franchise. At the end of the day, as long as you did the work to publicize it, no matter how badly people criticize you, you deserve and earn the credit.