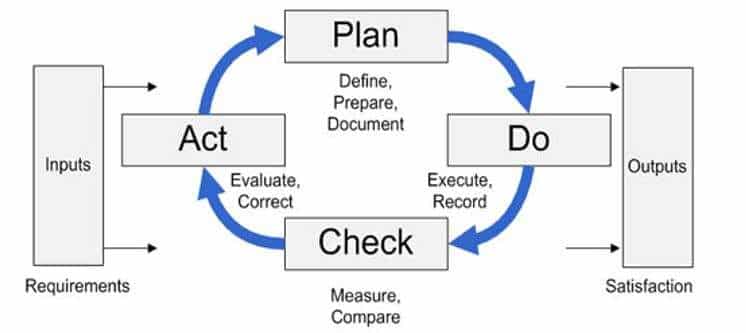

What Is Plan Do Check Act (PDCA)?

Sounds easy in principle, doesn’t it? Just plan your work and work your plan. So, why is “plan do check act” so difficult in practice? Using the Plan Do Check Act (PDCA) method is like climbing a hill: it starts out easy but gets harder the higher up you go. What Is Plan Do Check Act (PDCA)?

Plan Do Check Act Defined

It is known as PDCA for short and referrers to the process approach of management or the learning loop of discovery. PDCA is basic quality. Start with a target (a target is the minimum plan) and work on getting closer to the target and staying on target. That is PDCA.

Document Your “Plan”

The plan is really the easiest part of plan do check act. Start with goals that are measurable. Document your plan using objectives, policies, procedures, and forms. Assign individual responsibilities, and you’re done. When you’re building an ISO 9001 Quality Management System, this is not hard at all. But it gets harder, and pretty quickly.

What are examples of planning?

-

- Quality Plans, Control Plans, Safety Plans, Security Plans, Maintenance Plans

- Turtle Diagrams, Process Map, Flow Diagram, Value Stream Maps (VSM)

- Quality Policy, Mission, Vision

- Quality Objectives, KPI, Targets, Goals, Criteria

- Work Instructions, Procedures, Forms

- Risks, Opportunities, FMEA

- Training Requirements

- Equipment, gages

- Specs, CSR, Feedback

- Resource budgets

Using Your Plan Is the “Do” Part

What does the “Do” in plan do check act mean? This refers to using the policies, procedures, and forms to realize your objectives. This means collecting data, and populating your forms. You have to use your procedures and follow your policies.

While this may sound easy at first, keeping it up is the hard part — you may start with good intentions (that’s the “plan” part), but as they say, “Good intentions don’t pay the bills.” Your company has to follow through on its plan, and follow-through — commitment — starts at the top. Furthermore, management commitment isn’t an isolated event — it’s part of the company philosophy.

What are examples of “Do”?

-

- Process Data

- Inspection records for inputs, in-process, outputs

- Sign-offs, signatures, Authorizations, Approval Dates

- Training records

- Gage records

- Maintenance records

- Nonconformances “Check” Your Plan

“Check” Your Data Against the Plan

In case you missed that, let me say it again: “doing” takes management commitment. That’s a large part of what makes plan-do-check-act so hard. As management, you get so involved in running the day-to-day aspects of the business that you forget that you started with good intentions (the plan). It is not that the plan was ill-conceived; it’s that there’s more to it than a piece of paper. Plans need continual reevaluation — you need to constantly “check” your progress and adjust the plan accordingly. What’s so hard about checking the plan?

In the “check” step of plan do check act, you have to convert data into information. Charting data can make this much easier but even so, a chart is just a visualization of data. A chart is not information without a target. In addition, you need enough data points to show trends. How many make a trend?

Two points is a line, you need at least three points for a trend. But how much confidence will you have in three point trend? Not much. So ten points would build confidence in your trend. Instead of the last three months look at the last 13 weeks. It will confidence in your trend.

What are Some Examples of “Check”?

Creating information from data requires what Deming called “profound knowledge” about your system. It will help if you understand a little about statistics, which will make it easier to separate individual data points that represent the “vital few” or significant ones from the “trivial many”. Creating information out of data is not easy; often, it requires that you continually dissect the data and look at it from many different points of view.

“Act” On Your Results

So, let’s say you started with a good plan, you were able to collect some meaningful data, and you turned it into useful information. If you’ve accomplished this, the “Act” phase should be easy, right? Possibly, if you have a stable environment.

Today’s business world is an increasingly unstable environment — old and new forces are continually changing the dynamic. There’s local and global competition, widespread and affordable technology, weather and climate, cultures, beliefs — a host of forces acting on your business.

What are Some Examples of “Act”?

-

- Corrective Actions Preventive Actions (CAPA)

- Improvements

- Changes/ Management of Change (MOC)

- Feedback sent

Deciding what to do to compensate for or leverage external forces has always been difficult; it’s just becoming more so. But if you do a good job at the first three phases, the “Act” phase of plan-do-check-act becomes a lot easier. You just need to make better information out of your data.

An Example of Plan Do Check Act in Action

The Olympics happen every few years. Some Olympic records – and a few world records – are broken over the course of the event. You watch these athletes perform and you marvel at their power, their endurance, their finesse.

How do they do it? What makes them so special? Are they that different from you and me? Are they superhuman? No, not really. They’re just like you and me — well, maybe not now. But we all start out on equal footing.

The big difference? With a few exceptions, the athletes got their start fairly early in life. And almost from the day they laced up a pair of skates or strapped on skis, they had an ambitious, long-range goal — to be a pro, maybe even the next Wayne Gretzky or Hermann Maier.

Family and friends encouraged and helped them. Their parents, and then their coaches, made up their plan. They knew that to get the big goal, these future stars had to accomplish a lot of smaller goals, and they had to do it in step wise fashion.

The plan included competition, proper nutrition, and physical and mental training. Their coaches checked their performance in training and competitions. They analyzed the athlete’s performance, noted where they were reaching those small goals and where they weren’t, and revised the plan accordingly. Then, they executed the revised plan to improve performance.

They repeated this stepwise plan over and over until they reached their big goal, whether that was turning pro, making the Olympic team, making it to the medal round, or standing on the podium at the medal ceremony.

Think about that. They made a plan, executed it, checked their progress, and improved incrementally. What does that remind you of?

If you thought ‘Deming Cycle’, you’re right. Plan, do, check, and act — just like your organization should be doing (if it isn’t already). Your organization is just like that Olympic athlete. Improvement doesn’t happen overnight. It happens in stages, over time, following a plan.

Consider this: What are your goals for the short and long term? Do you have a plan to get there? Are you satisfied with your performance? More importantly, are your customers?

How do you get better? What will it take to make your firm stand out from the rest — to get to the Games, to the medal round, and maybe even the gold, silver, or bronze?

Are you monitoring and analyzing your business performance in order to improve? Are you looking for overnight success, or are you looking for incremental improvement over time? Do you adjust your plan when you don’t meet your goals?

Plan Do Check Act (PDCA)

So there you have it. Plan-Do-Check-Act — PDCA, for short. It’s one of the cornerstones of the quality world and the ISO 9001 standard. If executed correctly, it can help you get control over a seemingly chaotic world. Yes, it is hard to do PDCA right…but what’s worth doing well that isn’t difficult, too?

If it were that easy, everyone would be doing it…don’t you think?

Leave a Reply