Operational Excellence Leadership Consulting

Operational Excellence Leadership

Process expertise, business experience, and Lean Six Sigma ISO process improvement consulting experience, custom applied to your business to deliver World Class Business Processes that produce results – True Operational Excellence.

Lean Six Sigma ISO Process Improvement

- Build world class business processes using best practices, experienced Lean ISO process expertise, and time tested process improvement methods.

- Lean out your processes to remove waste, improve performance, and increase cash flow.

- Visualize your processes with value stream process maps to communicate work flows.

- Utilize standard work policies and procedures that drive consistency.

Starting Operational Excellence Leadership

Operational Assessment Management Tools

Operational assessment is one way to manage your way out of such a mess. With operational assessment you work your way through a logical sequence of steps to get your company back on track. The first step is to understand what the ultimate company goals should be, followed by firmly grasping what the department is actually doing (the current state of your core processes). Now you can use this information to help get started down the right path to the future state, which is the target or goal state.

Know Your Customer

The assessment begins by understanding customer requirements. Who are your customers? They could be internal customers or external customers or a combination, it doesn’t really matter. Identify the customers and then identify clearly what they want.

You may think you know, but have you asked them lately? Remember, Customer Requirements Are Not About You. Technology is changing methods all over the globe. Are you really sure you know exactly how the customer is using the product? A combination of simple surveys and in-depth interviews can help you collect the needed information.

Understand How Your Customer Uses Your Products

This leads to another important concept: you need to talk to your customers regularly, but you also may want to watch and observe how your customers use your product. They might not really know specific pieces of information to share with you that would be helpful, but observation could drive important changes; changes that will make it easier for you and your customer.

These kind of efforts drive satisfaction and loyalty, but they also improve effectiveness and efficiency. Understanding your customer is part of voice of the customer analysis.

Taking the perspective of the customer leads to knowing what the customer wants and values. This information is very valuable for operational assessment. Are you focusing on doing things that add value to the customer?

Are you wasting time, effort, and/or material doing things the customer doesn’t care about, or worse, doesn’t want to start with? Focusing on doing the things the customer wants and eliminating wasted efforts is key to creating an effective and efficient operation, which is the focus of Bizmanualz St. Louis Process Improvement Quality Consulting practice.

Process Improvement Requires Measurement

Now that you know what is important to the customer; how well are doing in these areas? The next step is creating clear objectives–specific measurable items that provide key performance information. Collecting data on performance should be part of everyone’s job.

It is easy, however, to get off track and create complicated measurements that generate difficulty and confusion and in turn cause departments and staff to lose focus, not gain it. The key here is to find objectives and measurements that are meaningful and not overly difficult.

Performance Measurement — More than Data

Frequently processes collect data that is similar to what is needed, it is just not being collected or employed properly or fully. Finding ways to easily collect important performance data without encumbering or over burdening an already busy staff is one of the biggest challenges of a manager, but a very important one. Don’t be afraid to modify or change things that aren’t working.

Pay attention to what is happening with the data and be flexible. If the data is too difficult to collect or is not being employed properly, it won’t be long until the staff realizes that collecting data is not really important, and they will abandon it.

Now that you are focused on clear objectives that are important to the customers and you have ways (measurements) of knowing how well you are doing in these areas; the assessment part becomes easy. Where are the gaps? What gaps should have priority? Trying to fix everything at once can cause the staff to lose focus again.

BUY-IN for Results

Getting staff buy-in also bears mentioning here. As always with Operational Excellence Leadership – honest communication is the key. Be clear that the goal of using assessment to improve the department is not to “fix” people; it is to improve the system and the environment that people function and operate in.

The ultimate goal is to make a better system that will make things easier and more clear for the staff. If you can communicate and follow through with these goals, and not fall into the trap of using measurements for “gotcha’s,” then most people will follow your lead and fully participate.

Closing the Improvement Gap

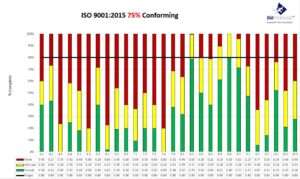

Those are basics of operations assessment. Figure out the gap between what you should be doing versus what you are doing, then create action plans to address the gap. We use a similar method when we help companies build or improve their ISO 9001 Quality Management System.

GAP Assessment

The first step is to do a Gap Assessment that clearly identifies what they should be doing to be in complete compliance with the ISO 9001 Standard versus what they are actually doing. Next is a clear plan of action that closes that gap between the current state and the actual state, so that soon what they are actually doing is what they should be doing.

We also apply these principles to our Well-Defined Processes training class, where a key feature for the class is to identify clear goals and objectives for processes, and then using measurement and review to bring processes under control. The same principle applies whether the process is on a factory floor or inside an office.

Our ISO 9001 Internal Auditing class here in St. Louis also uses assessment principles. There is an old saying that states, “To know which direction to go you first need to know where you are at.” Operational assessment puts legs to that idea.

Working with Bizmanualz provides you with process improvement expertise, lean six sigma methods, and the assurance that you are implementing best practices for world class process performance. Contact Bizmanualz Today. Download Free Sample Policy and Procedure Templates you can customize in MS Word for your business.

What’s the Value of Process Improvement?

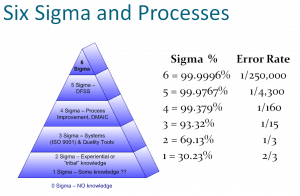

One way to look at it is by examining the reason for having a quality system in the first place. Let’s start by understanding the basics of six sigma, which define the maturity level of an organization’s management system. By that, we don’t just mean just a quality management system, but your entire system of management.

Sigma Levels

- 1 sigma = 67% error rate (or “2 out of 3 transactions are in error”)

- 2 sigma = 33% error rate (1 out of 3 transactions in error)

- 3 sigma = 6.7% error rate (1 out of 15 transactions in error)

- 4 sigma = 0.63% error rate (1 out of 160 transactions in error)

- 5 sigma = 0.02% error rate (1 out of 4,300 transactions in error)

- 6 sigma = 0.00034% error rate (1 out of roughly 290,000 transactions in error)

We define a system as “in control” when an organization’s processes exhibit a “3 sigma” (6.7%) or lower error rate. If your organization has not defined its processes, effectiveness criteria, and competencies, it’s more likely that you’re at a 1 or 2 sigma level. In order to achieve the “3 sigma” level, your company must consistently make no more than 6.7 errors per hundred — that’s a 93.3% success rate.

Operating at 93.3% Success Rate

Let’s say you see 60-70% as normal, which is about 2 sigma (66% success). The “delta”, or difference, between 2 and 3 sigma is about 27%. We believe that by adopting a quality process improvement program, you should see your success rate rise from 66% to 93%. That’s a 41% improvement over your current rate! What organization wouldn’t be interested in that?

Once you hit 3 sigma, your next goal is to improve to a 4 sigma level, then 5 sigma, and finally 6 sigma (which is as close as you can realistically get to “zero defects” in most operations).

Six Sigma Processes

Now quantify the benefit. What is 27 percentage points of success worth to your customers? The cost of implementing a six sigma process improvement program is small compared to the benefits to your customer (and, of course, to your bottom line). Process improvement practically guarantees customer retention, and can lead to customers advocating for you.

Implement an Operational Excellence Leadership Program

But if that’s not for you, don’t implement an Operational Excellence Leadership program. Learn to live with a 2 sigma error rate — and hope your customers can live with it, too.