How is PDCA Related to ISO 9001?

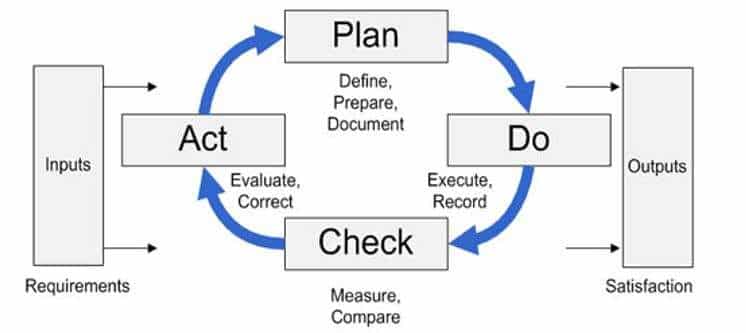

PDCA (Plan Do Check Act) Cycles refers to the PDCA wheel (Figure 1) and the continuous motion that PDCA requires. PDCA is not as easy as it sounds but, if you are interested in ISO 9001 Quality Management Systems (QMS), then you will find that an ISO 9001 PDCA cycle is the solid foundation. Master PDCA and you will become the master of your ISO 9001 QMS. But how is PDCA related to ISO 9001?

What Does PDCA Stand for in ISO?

Plan Do Check Act was developed by Dr. Walter Shewhart, one of the top ten quality gurus. Dr. W. Edwards Deming preferred to call it PDSA or Plan, Do, Study, Act because he felt that “check?” emphasized inspection over analysis. Most people spend most of their time on the first two, Plan and Do, and tend to neglect the Check and Act parts.

We have written a lot about PDCA and the process approach used in ISO 9001. Now let’s take a look at PDCA as it relates to ISO 9001 by breaking down the ISO 9001 standard into its main elements and then assigning them to each part of the PDCA process.

What you see is that each clause of the ISO 9001 standard contains a focus. clause 4 is focused on understanding the environment, leadership in clause 5, planning in clause 6, resource in clause 7, while clause 8 is focused on doing, clause 9 is focused on checking and clause 10 to act. What clause do you think people have the most trouble with?

Clause 9 and 10 are the most troublesome because they are focused on checking and acting. People get more satisfaction in planning and doing then they do in checking and acting. It is just human nature. So, to master ISO 9001:2015 you have to break the habit and budget more time for the checking and acting steps of clause 9 and 10. Now let’s take a look at each PDCA element and see how ISO 9001 aligns with Plan Do Check Act.

PDCA – PLAN

Your business should have an annual planning cycle that produces business plans that contain your: interested parties, vision/mission/quality policy, operational objectives, budgets, risk management actions, documented information standards, milestones, and new product/market/process introductions. Planning in ISO 9001 can make your company more competitive.

These planning elements are used in ISO 9001 in seven areas:

- Strategize the environment of the QMS (4)

- QMS Leadership (5)

- QMS Planning (6)

- Document the QMS (7.5)

- Manage QMS Resources (7)

- Plan Product Realization (8.1)

PDCA – DO

Your do steps are more frequent, possible occurring on a monthly cycle that produces data records for measurement and analysis as a result of executing the annual plans. A lot of your doing is focused on clause 8, Product Realization. Most of your documented information is produced in clause 8, which is product or service realization.

- Competence (7.2)

- Design, Develop, Realize (8)

- Purchasing (8.4)

- Product & Service Provisions (8.5)

- Record Nonconforming Product (8.7)

PDCA – CHECK

Once you have data from your doing steps you need to analyze or study the data (remember Deming’s PDSA reminding us to Plan, Do, Study, Act). We do not want to check to see if a step was done or check to see if data was produced. This is nothing but inspection. We need to analyze and understand what the data is telling us. We do this by converting the data into information.

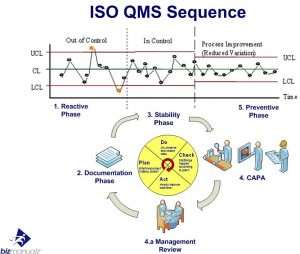

The ISO 9001:2015 standard clearly defines various check processes, which are cycles of measurement and analysis to determine how well the organization is executing the annual plans.

- Monitor & Measuring (9.1)

- Customer Satisfaction (9.1.2)

- Data Analysis (9.1.3)

- Internal Auditing (9.2)

- Management Reviews (9.3)

These are not one-time events. These check processes continuously occur, which brings to mind trend lines on charts as a way to convert data into information.

A monthly or quarterly check event is very realistic, although many companies choose an annual audit and management review or customer satisfaction survey as a sufficient check on the ISO 9001 QMS. I guess if you have an incredibly stable business model with little to no competition and a static environment, industry or market then maybe you can get away with an annual check. Are there any businesses like that anymore? But if the market is fast changing then you should be checking your QMS frequently (monthly) and taking the appropriate corrective actions.

PDCA – ACT

Actions taken — without undue delay — to close the gap, identified during measurement and analysis, between the annual plans and the data records produced during execution. Of course there is an element of act in the management reviews because after you review the required inputs you are supposed to assign action items to individuals to take the necessary corrective actions (and maybe preventive actions). Acting is the key to becoming ISO 9001 compliant.

ISO 9001 has a few clear action steps like isolating nonconforming product, taking corrective action, and maybe preventing risk too.

- Corrective Action (10.2)

- Risk Management (6.3)? (I know some of you want this here)

ISO 9001 PDCA cycle is not a singular thing. It is actually a series of embedded PDCA cycles. Clause 8 is not just about doing. Product realization is itself an ISO 9001 PDCA cycle that starts with planning requirements and realization needs. Next comes development (doing), development reviews (checking), and finally development revisions (actions). This same Plan Do Check Act cycle is occurring within training, documentation, purchasing, auditing, corrective action, etc. The whole concept of continuous improvement relies on PDCA.

PDCA and the 7 Quality Management Principles of ISO 9001

The Seven Quality Management Principles of ISO 9001:2015 utilize the philosophy of the process approach. This Plan Do Check Act cycle centers around these principles, which are used by management as a guide toward improving performance and identifying the main elements needed in a good and robust quality system.

1. Customer Focus

Organizations depend on their customers and therefore have to understand their current and future customer needs, meet their customer’s requirements and strive to exceed their customer’s expectations.

2. Leadership

Leaders establish a unity of purpose and the direction of the organization. They need to create and maintain an internal environment in which people can become fully involved in achieving the organization’s objectives.

3. Engagement of People

People at all levels are the essence of an organization. Their full involvement creates opportunities for their abilities to be used for the organization’s benefit.

4. Process Approach

A desired result is achieved more efficiently when activities and related resources are managed as a process, which has a beginning, middle and end. Inputs are clearly transformed into outputs, repeatedly.

5. Improvement

Continuous overall performance improvement is the objective of a successful long-term organization.

6. Evidence Based Decision Making

Effective decisions are based on solid information and objective data analysis.

7. Relationship Management

An organization, its suppliers, and stakeholders (interested parties) are interdependent and a mutually beneficial relationship enhances the ability of both to create value.

PDCA is Related to ISO 9001

An ISO 9001 certification is the start of a quality management system and to keep your ISO QMS working effectively you need to value each PDCA element equally and not favor one (i.e. Plan, Do) over the other (Check, Act). The Seven Quality Management Principles of ISO 9001:2015 utilize the Plan Do Check Act cycle as a guide toward improving performance and using the main elements needed in a good and robust quality management system. Put the two together and you get a continuously improving QMS.

Check out Bizmanualz Internal Auditor Training programs for more information on building Lean ISO Quality systems, creating well-defined processes, or getting more value out of your quality management system.

Good info…7 principles…you have missed out no.5 though????

ISO 9001:2015 took out Systems Approach to Management, it was considered redundant. Thanks for pointing it out.

Great Information! While developing software or building a company that works with technology or engineering-related projects, it might be worthwhile for you to apply for ISO Certification

[…] Bizmanual. (2016). How Can You Master the ISO 9001 PDCA Cycle? Retrieved August 19, 2016, from PDCA Cycle: https://www.bizmanualz.com/implement-iso-quality/how-are-pdca-cycles-used-inside-iso-9001.html […]