What Are the 3 Core Process Flows within Your Organization?

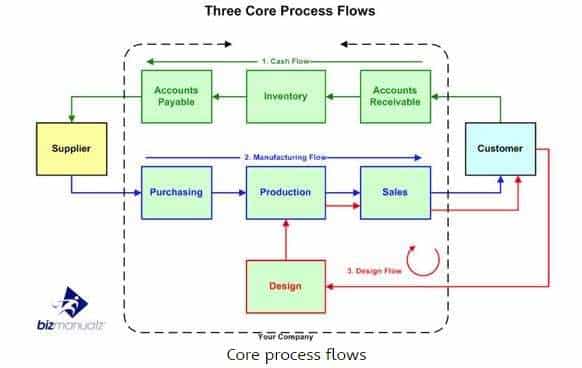

There are three core process flows within your company: your cash cycle, your manufacturing (or fulfillment) cycle, and some have a design cycle. What is the difference between these important cycles? And what are the 3 core process flows within your organization all about?

The Importance of Core Process Flows

Business process management (BPM) is all about identifying your core processes and then putting in place a system to manage your key business process. The cash cycle, your manufacturing (or fulfillment) cycle, and the design cycle make up the three primary processes with any organization.

The cash flow process represents the health of your business past. It is an accumulation of the activities initiated in the past. The manufacturing flow process represents the health of your business in the present. It is a sign of how well your business utilizes and consumes resources currently.

Finally, your design flow process represents the health of your business future. A lot can be learned about a business by understanding the three core business process flows: cash flow, manufacturing flow, and design flow.

Cash Flow Process

Your cash cycle reflects how cash is flowing into your organization and how it is leaving. It is depicted in the green lines in the core process flows diagram and is comprised of your accounts receivable, inventory and accounts payable processes. Your cash cycle is the life blood of your business and represents the health of your business.

Working Capital

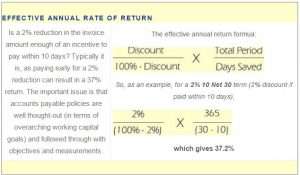

A healthy business has a strong and positive cash flow process, which means that you are collecting money from accounts receivable faster than you are disbursing it through account payable and accumulating inventory. Your cash cycle also determines your working capital needs.

If your cash cycle is negative then you will need to finance your operations with debt or equity capital. How do you know how much your operations need? Just calculate your working capital.

If you add the number of days of inventory to the number of days of receivables outstanding, and then subtract the number of days of payables outstanding then the result is the number of days of working capital your organization has tied up in managing your supply chain.

Investment in Inefficiencies

Your working capital is the investment you are making in the inefficiencies of your processes and procedures plus your investment in your suppliers’ and your customers’ inefficiencies too. The idea is to balance your cash process flows and drive down inventory to reduce your working capital needs.

The closer you can get to zero working capital days the more efficient your processes are. Next, there is your manufacturing cycle.

Manufacturing Flow Process

Your manufacturing cycle is found in the blue lines in the process flow diagram and should include your purchasing, production and sales process, which are your three inventory related processes. In traditional manufacturing organizations, the elements of the production process are separated into functional areas, each with individual goals to maximize their own functional output. Sub-assemblies or finished goods are built and held in inventory awaiting the next order.

The link between your supplier and purchasing determines your raw materials inventory needs. The link between sales and your customers determine your finished goods inventory. Your production process determines your work-in-process (WIP) inventory needs.

Demand-Based Flow

Manufacturing Policies Procedures documents.

Lean thinking is used to create a demand-based manufacturing flow. Demand-based flow is a form of build to order manufacturing that results in reductions of 50% to 80% in inventory, production cycle time and order lead time. How is this possible? Balancing the purchasing, production and sales processes results in reduced inventory and its resulting waste.

With cash flows, an unbalanced cash cycle produces negative cash flow and the need for increased financing. It is the same with the manufacturing flows. Unbalanced manufacturing flows require more inventory to compensate for all of the variation and unknowns, which increases your inventory, and in turn, your working capital needs.

Manufacturing Tied to Cash

Do you see how closely the manufacturing cycle is tied to your cash cycle. And yet some people believe more time, money, equipment or people is the answer. But I will let you in on a secret; You don’t need more resources. If you carry inventory then you already have plenty of capacity. Think about it, inventory comes from too much capacity not too little capacity.

Where else do you think it comes from? Raw materials: you bought too much. Work-in-process: your process batches are too big. And finished goods: your sales cycle is too long (probably because you don’t know your customers very well).

In manufacturing, it is all about replication. Increasing your cycle time and making your products faster will reduce inventory, increase quality and bring you closer to your customer. Just eliminate the delays in your processes.

Design Flow Process

How does design flow differ? In manufacturing and cash flows, our goal is to work towards zero defects and doing it right the first time. Both are laudable goals for replication processes that are already designed but how do we do that for iterative processes like the design phase? The answer-you don’t.

Iteration Versus Replication

Design flows are a little different than manufacturing flows. Design is about iteration, not replication. Designers will try many different approaches. They will stop trying based on achieving acceptable trade-offs with a constraint like time, money, specification, or manufacturability.

The product development design cycle is where one designs in quality, determines the characteristics for manufacturability, and all of the waste produced. Manufacturing results from design. There is another type of design, design to order, which is where service firms differ from manufacturing firms.

Replication Processes

When dealing with the cash or manufacturing cycles you are basically replicating a master process. In manufacturing, you make the same product over and over. Think of it as making copies of a master design. Your cash cycle is the same. You want accounts receivable collected in a timely and consistent manner. Each receivable is collected the same way according to a master process.

In replication you want each copy to be as close to the master as possible, hence your goal is zero defects from the master, while, at the same time, you want it done right the first time to maximize your productivity and reduce waste.

Iteration Processes

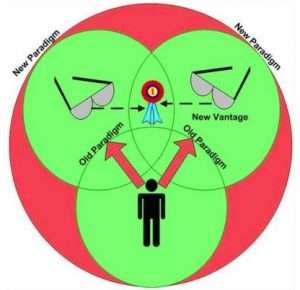

Design is about iteration, not replication. With design flow, we do not expect to have zero defects the first time. In other words, we expect that a new design will not be right the first time. So we produce an idea and then refine it again and again until we are satisfied that the new idea meets the requirements.

Design is an iterative process of refinements. It is the nature of the design process itself. In the design cycle we try out new concepts which expand our paradigm barriers. Your paradigm limits your thinking by literally creating barriers to new ideas. From these new vantage points we see more new ideas, which then move our paradigm barriers farther out.

Brainstorming

Is your organization designed for change? You see innovation and design come from brainstorming new ideas, seeing the same things a different way, and thinking outside the box. The more new ideas we try the more we refine the concepts we are focusing on and the better the product design becomes.

Law of Diminishing Returns

Iterations come from new ideas but there is a limit to the refinements we can make. As we approach this limit the design is considered “good enough” and we move on until new information, perspectives or old constraints are removed. This is the law of diminishing returns at work.

Thinking Outside the Box

A lot has been written about thinking outside the box when we talk of lean manufacturing and the importance of balancing your manufacturing flow. But for many, the critical path involves design as in design to order, engineer to order, or build to order.

Three Core Process Flows

We have seen how similar the three core process flows are yet so different. Each of them within a company: your cash cycle, your manufacturing (or fulfillment) cycle, and your design cycle. Design flows differ from manufacturing or cash flows because they are based on the principle of iteration versus replication and require one to continuously innovate to keep the design cycle moving.

To learn more about implementing continuous process improvement within your organization, attend the next improvement class or learn How to Create Well-Defined Processes and to document processes. ISO 9001 Internal Auditor classes are forming now for Internal Auditor or Lead Auditor. Call for information on having your own private in-house classes today.

Leave a Reply