flow

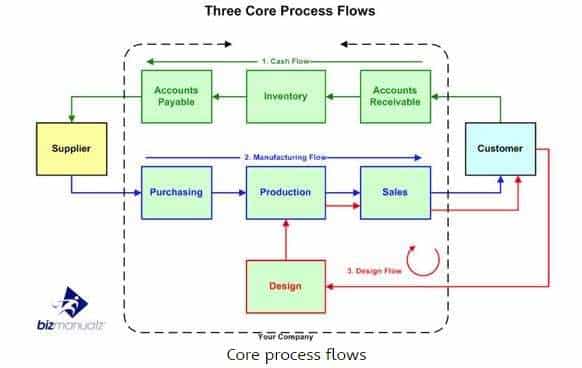

A look at four cash flow control procedure areas in which you can save $250,000 each — for a total of $1,000,000. Learn more now.

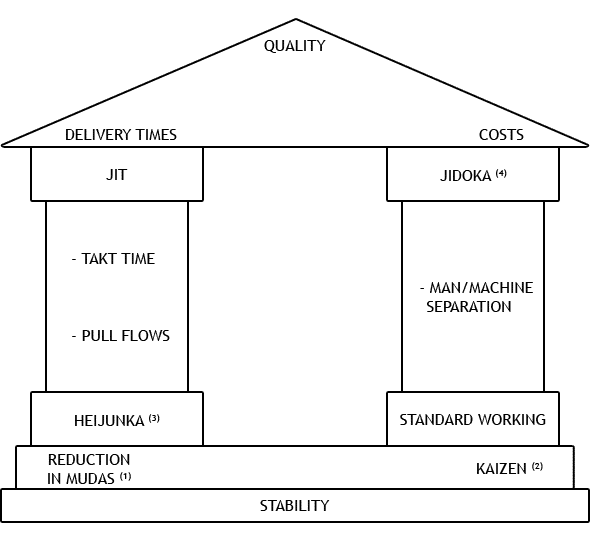

Read moreProcess improvement in a lean system is driven by the employees and NOT management.

Read moreHow does manufacturing flow differ from design flow, and how can you use these core processes to implement continuous process improvement?

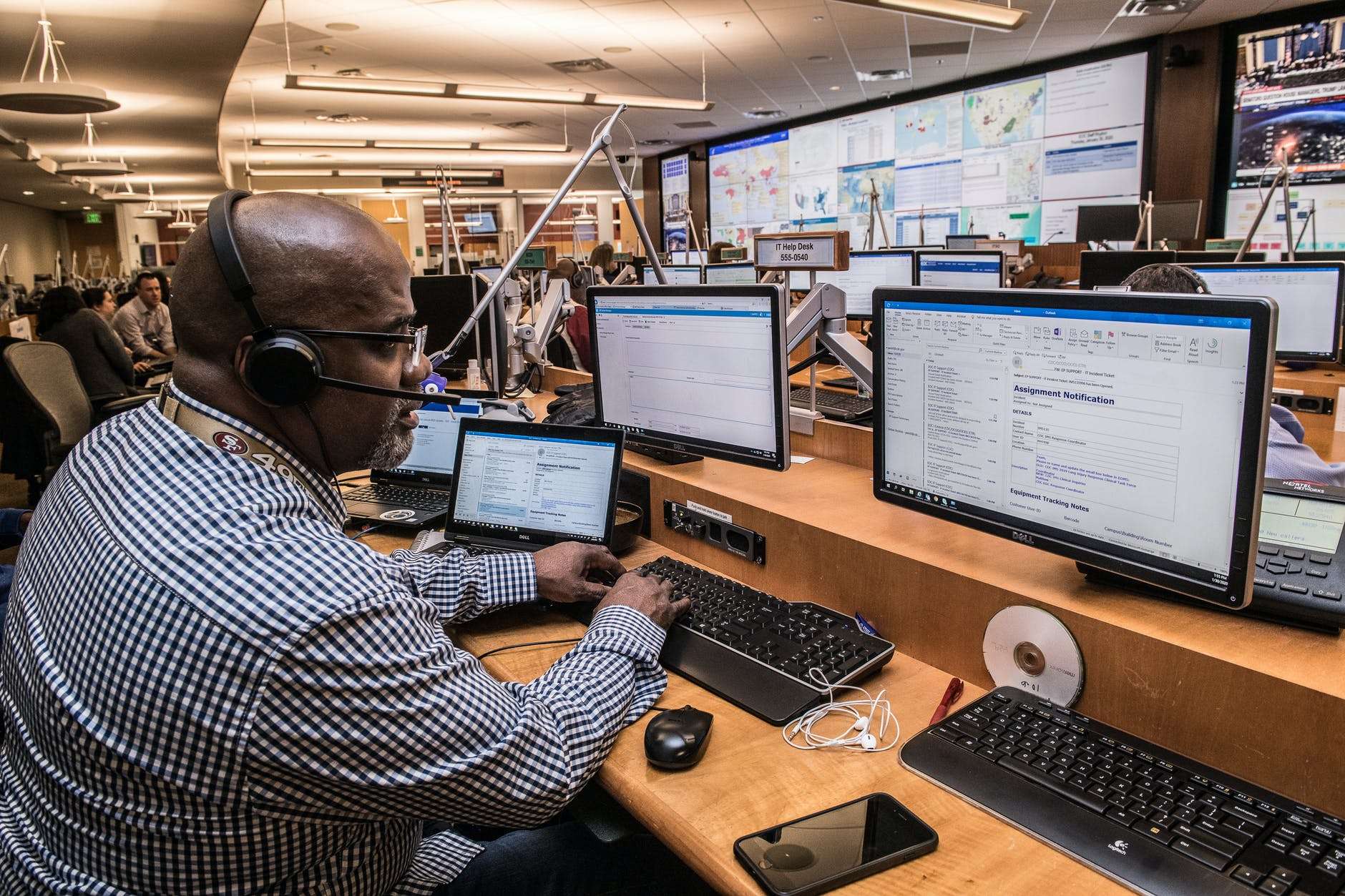

Read moreThe accelerated rate of change in business means that the rate of adopting new skills must also change.

Read moreDo you consider the total cost of ownership and ensure that your workers are competent and aligned to the product flow instead of by function?

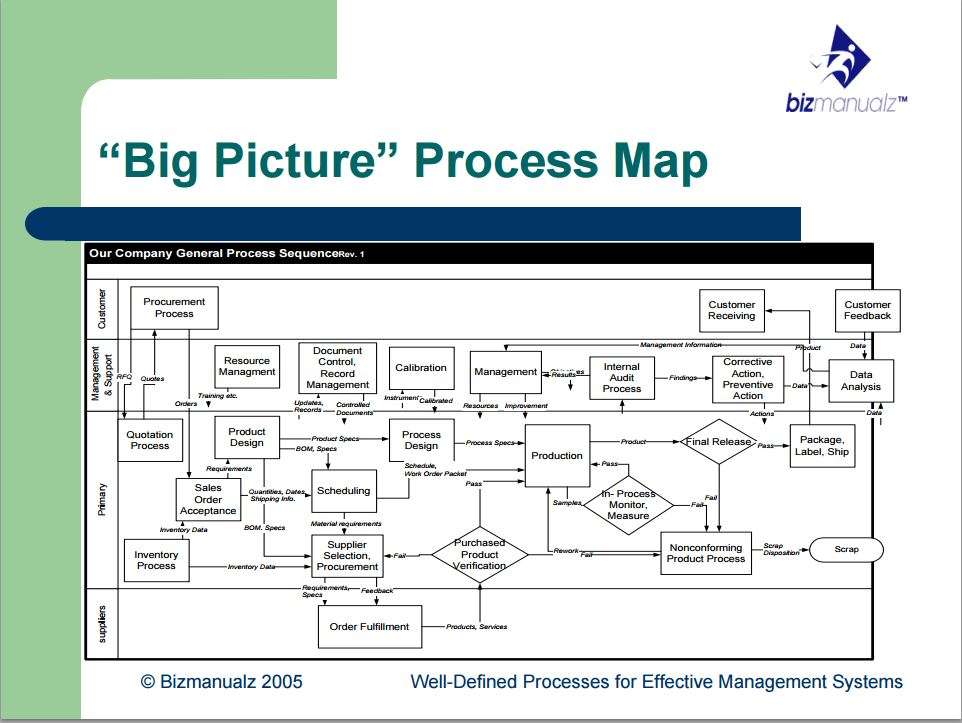

Read moreWorkflow Diagrams and Rendered Process Maps translate abstract UML symbols of squares and diamonds into graphical images, which tell a more complete story.

Read moreLean Thinking is a mindset, it is about focus, removing waste, and increasing customer value. Lean is about smooth process flows, doing only those activities that add customer value and eliminating all other activities that don’t.

Read more