How Can Manufacturing Companies Reduce Costs?

As a manufacturer, you likely have to deal with large investments and the high costs of production, which is also referred to as the Cost of Poor Quality (COPQ), that often represent one of the biggest issues in the industry. If that is the case, finding new, smart ways to save money in an effort to increase your profit margin might be your number one priority. How can manufacturing companies reduce costs?

6 Efficient Ways Manufacturing Companies Can Reduce Costs

But rather than drastically cutting resources to one department, which could significantly affect the quality of production, it might be best to grow your bottom line by utilizing a number of smaller cost-reducing measures that will quickly add up to large savings. To that end, here are some of the best and most efficient ways you can reduce expenses in your manufacturing company and increase efficiency.

1. Reconsidering Labor Costs

When attempting to reduce your expenses, the cost of labor is a great place to start. But even though many employers might believe trimming their current workforce is a quick cost-saving tactic, this is actually not the case, as hiring and training new workers can often come with a number of hidden expenses.

One of those hidden expenses is turnover, which is directly linked to how your treat your employees. Because of the continual need to go through the recruiting process, having a high degree of worker turnover can cost a firm a lot of money.

Instead, a wiser business tactic would be to ensure you have a core team of professional, experienced, and efficient workers to manage, which can easily be achieved by reviewing your current employees, improving workplace safety, investing in excellent training opportunities, and outsourcing work for specific, uncommon projects.

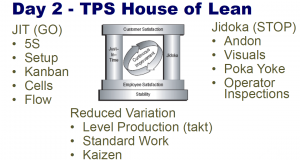

2. Implementing Lean Manufacturing

There are many common misconceptions about lean. Most companies deal with metaphorical lean waste that disrupts production in one form or another, whether it’s a waste of time, space, or resources. While this might mean not utilizing your employees’ skills or manufacturing tools to their full extent in some instances, in most cases such waste will come with significant financial costs. Lean manufacturing aims to improve production by eliminating this metaphorical waste, allowing you to achieve more with less.

Whether you decide to downsize your space, improve efficiency by cutting down on time, or even utilize less equipment and resources, implementing some lean manufacturing practices will allow you to significantly reduce your production costs.

3. Finding Better Waste Management Solutions

Of course, most businesses will have to handle literal waste during production as well, and likely already have certain waste management solutions set in place for the dangerous types of waste they are legally required to dispose of consciously. However, there are some forms of chemical waste, such as hydrogen sulfide, that aren’t considered to be contaminants, but could still cause stains, discoloration, tarnishing, and corrosion, all of which can lead to additional costs if not dealt with correctly.

If this is the case with your company as well, it might be best to invest in efficient hydrogen sulfide removal solutions. Besides ensuring the concentration of this chemical is as low as possible, these solutions will also help to prevent contamination and reduce your overall waste.

4. Reducing Energy Consumption

Although energy might be essential for the functionality of any business, these costs can quickly add up if you’re not careful about consumption, which is why investing in energy-saving solutions can be a great way of reducing your expenses and following through with continuous improvement.

If you don’t already have an energy conservation plan set in place, introduce measures such as LED lights, motion-sensor lighting, smart thermostats, updated HVAC systems, energy-saving manufacturing equipment, strategic machinery use, as well as scheduled startups and shutdowns. No matter how small, every effort to conserve energy can result in significantly lower overall costs.

5. Improving Maintenance Routines

While waiting until your machinery breaks down to fix it might seem logical to some, it can actually come with higher costs in the long run, and it might even counter your waste-reducing efforts. Similarly, outdated and poorly maintained equipment can add to your overall expenses as well, both when it comes to energy consumption and high costs of repairs.

Instead, the wisest decision any manufacturing company can make is to maintain their equipment regularly. Aside from essential aspects such as cleaning, lubricating, and replacing filters, this should also mean conducting routine audits of the safety, efficiency, and operational condition of your machinery, in an effort to save money on costly replacements and repairs in the long run.

6. Investing in Automation Systems

Human labor can hardly be fully replaced in many industries, but it can be combined with technology for optimal efficiency. One simple way automation can help your business is by utilizing technology to reduce costs by automating routine tasks such as customer support, data collection and migration, backups and restoration, employee requests, attendance tracking, invoicing, payrolls, etc. If you have the means to invest in more refined technology, solutions like collaborative robots can be brilliant for conducting quicker, more effective work, as well as delivering higher quality output, thus representing a great return on investments.

Efficient Ways Manufacturing Companies Reduce Costs

The manufacturing business always comes with high investments and costs of operation, as an unavoidable aspect of the industry. There are many hidden costs to offshore manufacturing, so that is not a great solution for many. However, simply by implementing some of the cost-reducing measures mentioned above, you might be able to efficiently lower your expenses, effortlessly leading your company to a more successful and profitable future.

Leave a Reply