What’s the Difference Between Leadership and Management?

It’s time for manager’s and leadership to step up and chart the course for the year ahead. Leaders motivate others by defining goals, setting standards, and determining the minimum acceptable performance. Managers measure and monitor the goals to ensure acceptable performance. In other words, leadership is a self fulfilling prophesy. What’s the difference between leadership and management?

What Does Leadership Look Like?

Leadership is about setting the bar or target for success and not settling for less. For example, in continuous improvement we set lean thinking goals of zero defects or zero tolerance for waste. Then we implement programs to achieve such goals.

What happens if leadership sets goals of 10% defects or waste as acceptable? That means that 90% performance is good enough for the organization. Now leaders have set a vision of tolerance for waste. Now workers can happily produce waste and defects. Think that this is not how leaders operate? Let’s see…

Leadership Through Inventory Turns

The average inventory turns for the S&P 500 is around 12, which translates into 30 days or one month of inventory on hand. This means that inventory turns over once a month or 12 times per year. Of course by average we mean that some companies are above 12 and some below, but 12 is a typical inventory level for many companies. But is 12 a good number?

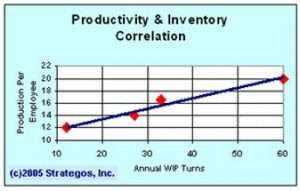

Inventory hides waste that results from various process defects within an organization. Basically problems create inventory. Five to fifteen (5-15) inventory turns per year is considered average. Think of this as you are no worse than anybody else. Companies with inventory turns of 15-25 are considered good. Turns over 25 are considered very good; 50-100 inventory turns a year (i.e., once or twice a week) is considered great.

Outstanding Inventory Performance

Outstanding Inventory Performance

Firms with outstanding inventory performance excel on other dimensions such as customer service, delivery, and productivity. The following chart (courtesy of Strategosinc.com) shows the results from one of many studies that support this contention. The study examined four similar firms in several countries. The chart shows their (work In Process) WIP turns and productivity in units per employee.

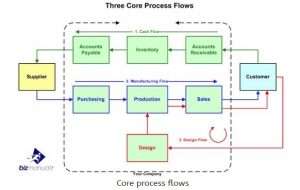

Inventory turns is a composite measure of an organization’s overall efficiency and is made up by adding the inventory needed by the three primary cycles:

purchasing cycle + manufacturing cycle + sales cycle

Which represents inventory consisting of:

raw materials + work in process + finished goods

Companies with low inventory turns have high inventories.

- High raw materials stocks are used to compensate for long lead times to reorder (slow suppliers) or large minimum orders (batch size), which both represent our supplier or shipping inefficiencies.

- High work in process stocks are used to compensate for unreliable/long manufacturing processes, bottlenecks (constraints), or large manufacturing batch sizes which represent our manufacturing inefficiencies.

- High finished goods stocks are used to compensate for infrequent orders (slow moving items) or chaotic demand, which represents our sales and marketing inefficiencies.

Fighting Process Inefficiencies

Faced with all of these daily inefficiencies what does leadership and management do? Typically the answer is managers raise prices to cover the inefficiencies. In effect, management is settling for less (which is the opposite of what management leadership is about!) and documenting it into their organizations’ goals. How do we know this is true? Study the stock market.

If you study the financial statements of various companies, you’ll see that companies with high inventory turns have low margins and those with low turns have higher margins. A supermarket turns their stock in days because they have to or it may spoil. By comparison high tech companies have much higher margins, but much lower turns because they have to bring in stock from Asia.

What eventually forces management leadership to change their paradigm and raise their standards? Competition, which drives down margins. In order to compete with lower margins you need higher inventory turns. If you cannot drive your inventory turns down and you cannot pass your inefficiencies on to your customers, you are out of business. Of course, the best strategy for leadership is to create a cash flow machine with high inventory turns and high margins.

Great Management Leadership Companies

Great companies don’t settle for less, they don’t tolerate waste, and they strive for zero defects in their processes. Great companies reach such goals by continually improving their processes. As their processes improve, their inventory turns rise and their competitors struggle.

Current examples of great management leadership companies include Dell, whose relentless focus on their supply chain has driven them to the top of their industry, and Southwest Airlines, whose focus on turning planes at each airport stop has made them the most profitable in commercial aviation. Want more examples? Perform a “stock screen” for companies with above average inventory turns and above average margins.

Successful process improvement programs are created from powerful visions, solid strategies, and clear goals and objectives. But they all stem from great management leadership first.

Difference Between Leadership and Management

The difference between leadership and management is: Leaders inspire people by establishing objectives, establishing standards, and identifying the minimum acceptable level of organizational performance. Managers measure and monitor goals to ensure that they are met. Which are you–manger or Leader?

Leave a Reply