Do Lean and ISO 9001 Go Together?

Lean ISO 9001? To many of you this will seem like a contradiction in terms. The term Lean and ISO 9001 are not generally used together, but why not? Does a Quality Management System (QMS) have to be complicated and cumbersome? Do Lean and ISO 9001 Go Together?

Lean and ISO 9001

I’m reminded of speaking to an adult evening management class at the local junior college years ago. At the start I asked the class of about 20 students, “How many of you have heard of ISO 9001; please raise your hands?” Then I asked, “How many of those with your hands up have heard or believe that ISO 9001 is a documentation nightmare?” Not a single student lowered their hand. I went on to explain how ISO 9001 was only a documentation nightmare if a company chooses to make it so. The documentation myth of ISO 9001 persists to this day.

I recently had a telephone conversation with a manufacturing Quality Manager requesting some advice. His dilemma is that as his company nears the completion of their QMS conversion from ISO 9001 to IATF 16949, he has a couple of key suppliers who refuse to pursue a formal registration to a Quality Standard. Their rationale is that they cannot justify spending a lot of money for a piece of paper or a plaque.

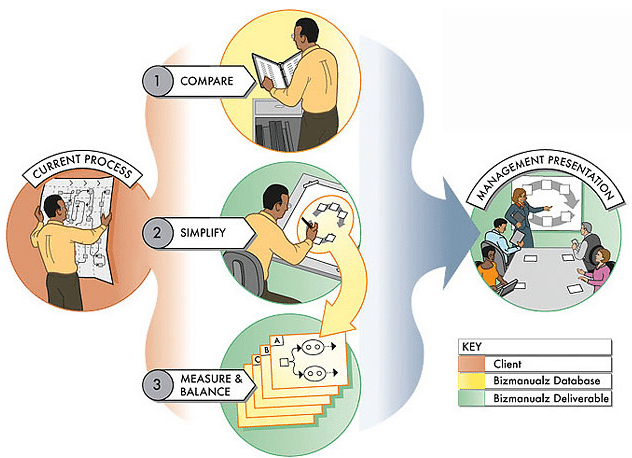

Lean Simplifies the QMS

My response to the Quality Manager was, “the current ISO 9001:2015 standard does not require a simple Quality Manual or any procedures to document the 9001 Quality System. To show they are at least moving toward a formal system, all they really need is evidence of effectiveness.” I further added, ” It does not cost a lot of money, unless a company chooses to develop a complicated Quality System. In fact, a formal Quality Management System should help a company to become more competitive, and therefore more profitable! But, whatever they do, they should keep it simple and build a lean ISO quality system.

After further discussion with the Quality Manager it was clear that his understanding of the requirements is that a lot of procedures and documents are needed. So the myth of ISO 9001 being a documentation nightmare is still a common misconception at many levels. This manager is definitely in the old school of Quality Systems as a documentation nightmare. He was amazed when I explained to him different methods of fulfilling the Quality system requirements, along with the concept of lean and ISO together.

Start with Simple Documented Information

So what is a Lean ISO 9001:2015 QMS? Well, a good place to start this discussion is with the Quality Manual. But, the ISO 9001:2015 standard makes no mention of a quality manual, it is now optional. This means you can keep your old one if you like, or you can throw it out. So what happened to the ISO 9001:2008 requirements for a Quality Manual?

No Quality Manual Requirement

You are still required to determine the scope of the QMS (clause 4.3) and make it available as documented information. Under clause 4.4.2 you must maintain documented information to support the operation of processes. But ISO 9001 does not prescribe how to do that. If you choose a quality manual as the place to document your system, great. Alternatively, you could document the system in a business plan, PowerPoint presentation, or through a lean visual management method like a performance scoreboard.

There is nothing in this requirement that says a ISO 9001 Quality Manual needs to be 50 or 20 pages long. It does not require pictures, the organization’s legal structure, or any additional details. However, most Quality Manuals seem to follow the pattern of addressing each and every ISO 9001 “shall” statement by essentially repeating the standard’s requirements. What an incredible waste!

Don’t Make Extra Work for Yourself

The Registrar and the Registrar’s Auditor(s) know the content of ISO 9001:2015; there is no need to repeat it back to them. What about our customer’s you may ask? Usually a customer is not going to read a 30 page Quality Manual. If they do require a copy, they will merely file it and check off that you have one; so why not send them a simple Quality Manual? Don’t make extra work for yourself, it will only lead to a potential audit finding.

Design Documented Information to Meet the Standard

Let’s look at the specific requirements for ISO 9001 compliance. A brief description of the scope of the organization’s Quality System, followed by a list or paragraph noting and explaining any exclusions to ISO 9001 clauses. So we are up to 1/2 to 2/3 of a page and we comply with 4.3.

Clause 4.4.2 calls for documented information to support the operation of processes. It will help to simplify this requirement. Here you could use your old procedures, work instructions, process maps, lean value stream maps, lean flow diagrams, or more lean visual management. But there is no requirement for procedures.

While it is still at the discretion of an organization to include quality assurance policy statement and procedures, the following example may help with this determination. Perhaps an organization has a small staff and sub-contracts much of their activity. Clause 8.4.2 defines the type and extent of control over any externally controlled (outsourced) processes. This can lead to a short paragraph or a few additional sentences in the scope portion of the Quality Manual. However, organization can produce documented information (quality manual) identifying their activity related to clause 8.4, Control of externally provided products and services. This is where the control and identification of the sub-contracted activity should be identified.

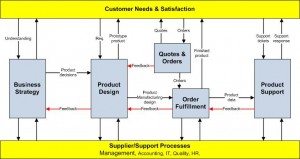

With the document list, our Quality Manual has increased by about a page. Now let’s consider ISO 9001 section 4.4; the interaction of processes. This is often the most difficult task in developing documented information (quality manual). Unfortunately, many organizations do not understand how their business works. My recommendation is to just do a simple overview of how the company functions and how processes interact. A good way to do this is in a flow chart, or process workflow diagram. A short 1 or 2 paragraph description can also be added, depending on the complexity of the organization.

Lean and ISO 9001 Finishing Touches

When you use our online document management system, procedures, records, and rights to use or edit them are managed within the web-based system. Deployment — and control — become very easy.

Now we have about a 2 to 2 1/2 page Quality Manual. Stop! You are done! You have met the requirements of an ISO 9001:2015 Quality Manual. I know you want to do more. Most organizations will want an attractive cover page with the organization’s logo and/or a picture of the facility. Most organizations will typically want to have their approval signatures included in the manual and a revision history. This can be included in the manual or kept separate;it is the organization’s choice. So with a cover page, the approval signatures and brief revision history we have added two pages.

After adding these we now have a 4 to 4 1/2 page Quality Manual. Are we finished? Yes! Stop! There is no need to add more. It is hard to break the paradigm of a lengthy documented information (quality manual), so there will be the pressure to add to it. A good Lean Quality Manual, however, should be two to five pages long. There is absolutely no reason to have an ISO 9001:2015 Quality Manual that is more than eight pages in length.

Now we have a lean and functional Quality Manual. It is easy to maintain and distribute, whether electronic copy via a document management system or hard copy, which eliminates waste. People are more inclined to actually review it due to the small size, so we have added value. It can be bound in a variety of formats for presentation to customers or sent to customers electronically. Why not go all the way and have an all electronic copy documentation system.

It is interesting that you use lean and ISO 9001 in the same sentence because they are generally not used together. That has given me a lot to think about however. Like you mention, why not? I don’t see what the harm could be. In fact it might even be pretty beneficial.

A lean ISO system is possible. The new ISO 9001:2015 eliminates the Quality Manual and Procedures, and focuses on results. That is a lean ISO system.