What Is a Well-Defined Process?

The simplest and best definition of a procedure is “a documented process”. But that just begs the question of ‘what is a process’. When we build processes we want them to be clear so people can understand and follow them. We need them to be well-defined. Learn about what process maps are and what is a well-defined process.

What Is a Well-Defined Process?

Think of any business process. Of what does that process consist? A number of ordered steps. Are those steps followed from start to finish and they’re done? Not exactly. Your processes aren’t “one and done”, are they? Of course not. Those are events, not processes. We need to document events, but not for the sake of repeatability.

Processes are events or tasks we want to repeat an unknown number of times; we’d like some processes repeated indefinitely. If we want our business processes to be consistent — to yield predictable, consistently good results — we need to document them.

We document processes (i.e., write procedures) to ensure consistency and quality of the results. We also document processes so we can train (and retrain) employees. No matter who is performing or supervising the process, no matter when or where they’re taking part, we want quality and consistency.

To develop what we call a “well-defined process”, we use a couple of simple, effective process modeling tools: the SIPOC Diagram and the Process Model.

The SIPOC Diagram

This tool gets its name from its five components:

- S – Supplier

- I – Input;

- P – Process;

- O – Output; and

- C – Customer.

This tool needs little explanation: because it’s visually oriented, the SIPOC diagram is very effective communicating, breaking down language, and other barriers. It helps people understand the purpose for the process and, when linked with similar diagrams of other processes, explains its relationship to other business activities.

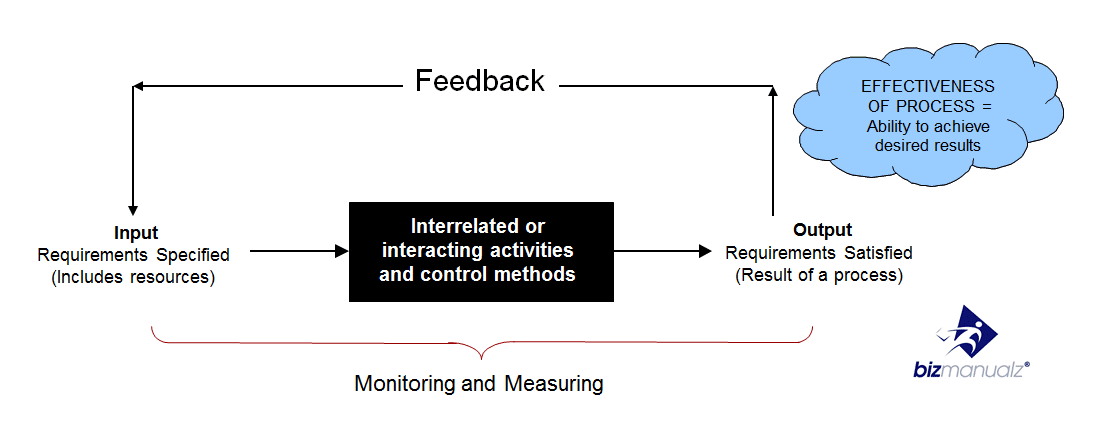

The Process Model

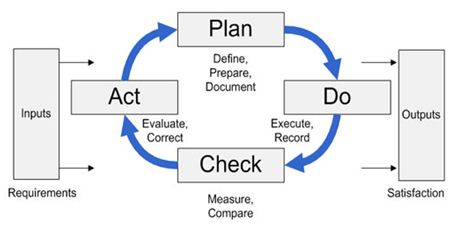

Like we said, a one-time event is not a process, just like a one-time repair is not a corrective action. A true process is a cycle — the Deming PDCA Cycle to be exact.

This ISO process model does an excellent job of illustrating a typical process. A well-defined process should answer your questions about the processes methods for Plan, Do, Check, Act:

- You PLAN the process, establish process objectives (what the result should be), state the various requirements (customer, regulatory, standards-based, internal, etc.), and describe how you will get from point A to point B and back again;

- You DO, performing the process and collect process data; The data element is critical for providing feedback to determine if the process is control.

- You CHECK on the process, reviewing the data you’ve collected and analyzing process performance (not just according to stated objectives, but also for variability, consistency, and trends); and

- You ACT on your review findings, either continuing with the process unchanged or modifying the process to make it work better and implementing the process with those revisions.

Ensure You Have a Well-Defined Process

The PDCA Cycle is the ideal framework for developing business procedures. That’s why at Bizmanualz, we use the process model as the basis for our procedure templates. The process model works for any procedure, whether it’s in Accounting, Human Resources, Sales/Marketing, or any of your other departments.

You’ll find that when you use these simple and effective tools to guide your procedure development, your processes will be well-defined processes and you’ll reach more of your objectives. Thanks once again for your time and your comments.

What about you? Have you used these tools recently? Did you find that they were extremely helpful, or not at all? What tools do you use to develop your procedures? Have you used Bizmanualz policy and procedure templates? What did you think of them?

Leave a Reply