Why Root Cause Analysis Is the Foundation of Corrective Action

You have identified a problem, and you have made an immediate correction to fix it for now. How do you make sure the same problem doesn’t happen again? The goal of implementing corrective action is to identify and to address the root cause of problems so they don’t reoccur. This is why root cause analysis is the foundation of corrective action.

Correction Can Be the First Step to Root Cause Analysis

Root cause seems to be an appropriate term for several reasons. First of all, it focuses on the source of the problem. Next, it implies that the source or true cause of the problem is hidden and out of view, which is why a root cause analysis is needed to improve processes.

Simply addressing the symptoms without addressing root cause sometimes creates more problems in the long run. A classic example is expedited orders. A customer calls because an order is late. So, to expedite it, someone takes time and effort to move the order more quickly through the process.

Of course, in giving this order priority and moving it ahead of other orders in the pipeline, more orders are going to be late. Now more customers will be calling, more orders will be expedited, etc. The process of expediting this order, in effect, causes a chain reaction and negative spiral.

Does that mean that when a customer calls because an order is late that we shouldn’t expedite it? Of course not. The point is that expediting the order shouldn’t be all we do. We should investigate why the order was late and collect some basic information. How often do orders ship late? How often do customers call and complain about orders being late? What is the apparent reason this order was late?

Not All Problems Call for Corrective Action

At this point, we are just trying to collect some initial data to determine if this warrants corrective action. Not every problem or nonconformance requires corrective action. How to determine if a corrective action is needed varies by organization.

It may be left up to individual employees or process owners, some might have a CAPA (Corrective Action Preventive Action) committee, and others may leave it to management. The need for corrective action should be evaluated along several dimensions.

How often does it happen? How important or critical is the issue? How are customers impacted? What is the cost of taking action versus not taking action? The answers determine if there is need for corrective action.

In our example, if this was a rare event due to a special case with minimal customer impact, then perhaps we perform the correction (expedite the order) and do nothing more. If orders are regularly late, or if the customer was severely impacted, then it is a candidate for corrective action, which starts with root cause analysis.

Root Cause Analysis Tools Identify the Cause of Problems

Once you decide that corrective action is appropriate, there are a multitude of root cause analysis tools to employ. The tool you select should depend on the skill and training of those employing root cause analysis, and on the complexity of the issue you are trying to solve.

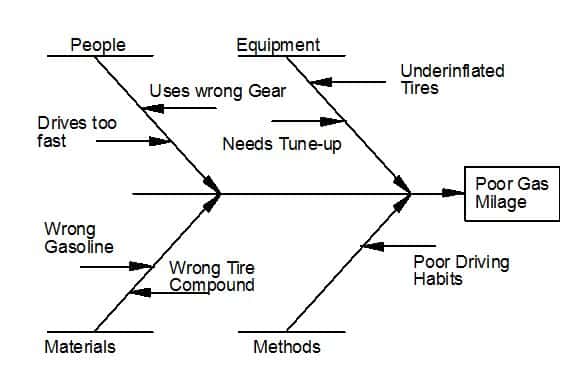

While the complexity of corrective action tools range widely from fairly straightforward (i.e. Five Whys) to fairly complex (Current Reality Tree), most are found to be fairly effective at reaching potential root causes if properly carried out. Perhaps the most popular tool, and in the middle in terms of complexity, is the Fishbone Diagram (also called the Cause and Effect Diagram or Taguchi Diagram) as shown in Figure 1. More experienced and skilled teams seem to be more effective at using complex tools.

The Team Is More Important than the Tool

However, the largest factor determining the effectiveness of root cause seems to be, according to the research, how effective the corrective action team works together. Critical areas seem to be a knowledgeable facilitator, how comfortable the team is challenging assumptions and critically evaluating the direction of the analysis.

Another important factor is including corrective team members from outside the area of focus. Someone not locked into a certain way of thinking can bring a fresh perspective to the root cause analysis, which in turns leads to thinking outside of established patterns.

Besides the experience of the team, the type of problem or nonconformance should also play a role in selecting a quality tool for corrective action. For example, using a simple tool like Five Whys might seem appropriate for determining why a customer’s order was shipped late, but where issues of health, safety or other high risks are involved, a more comprehensive tool like Current Reality Tree, Cause and Effect Diagram, or Interrelationship Diagram would be more appropriate

Steps to Root Cause Analysis

Concrete Steps

There are many root cause analysis tools, and they all seem to have their supporters and detractors. You should choose which ever tool fits your organizational needs the best, or even mix and blend methods if you feel it is effective for your purposes. Then training should communicate established root cause analysis practices throughout the organization.

Which ever method you choose to use in your organization, there are some common areas of importance:

Define the Problem

Clearly define the problem or non conformance with the facts. You are not solving the problem, yet. Just making sure you understand the problem you are going to solve.

Gather Information

Gather all the information you can related to the problem. Interview people involved with the issue, collect samples of the problem, and take note of environmental factors that may have an influence on the problem.

Brainstorm

Brainstorm to identify inputs, suppliers, and activities related to the problem, and note any that might have a potential causal relationship with the problem. This is where a Fishbone diagram can be used to organize the results into the five “M” categories (man or people, materials, machines or equipment, methods, and mother nature or the environment).

Research and Experiment

Use research and experiments (hard data) to eliminate potential causes not associated with the problem. For those remaining, identify which causes if removed or changed will prevent recurrence. Remember, there may be more than one potential cause, but the goal is to identify as few potential root causes as possible.

Error Proof

Identify ways to reduce or eliminate the causes to prevent recurrence. Focus on activities that are within your control and do not cause other problems. Simplify by taking steps out of the process.

Implement the Solution

Implement the changes discovered in the previous steps and note the results.

Verify the Solution

Verify after an appropriate period of time that there is no reoccurrence. (Some organizations require that verification be performed by someone not involved in the root cause analysis.)

Repeat

If there is reoccurrence of the problem (not all root cause analysis will be effective the first time) then go back and repeat the process. Use what was previously learned to identify and eliminate other possible causes.

Periodically verify the effectiveness of the corrective action program and the associated root cause analysis. If corrective actions are not, in a large view, successful at identifying root causes and preventing reoccurrence, then new methods, a new process, or additional training may be needed.

While the many tools available for conducting root cause analysis may all be effective, their effectiveness is very dependent on how they are implemented: data collection, involvement and training of team members, a communicative and qualified facilitator, how questions are asked and answered, and follow-up verification. They are all critical to the success of the root cause analysis process, upon which corrective action relies.

Another important factor to consider is when to stop searching for root causes, and instead select action items to address identified root causes. If you keep searching, you can always find more and more potential root causes. Use experience, knowledge, and intuition to know when you have dug deep enough looking for causes, and now it time to take action.

Problems manifest themselves in many ways but to truly solve a problem you must make sure you have found the root cause. A good place to start is by understanding the top ten root causes of business problems you will encounter.

Systemic Causes of Business Problems

People don’t make mistakes. Systems make mistakes. If you have a system for training, well-written procedures, following-up on procedure usage (i.e. internal auditing, metrics, rewards), developing competent employees for the role they are placed in, updating and innovating methods, attention to detail, disciplined maintenance, quality designs, constant rewards and incentives for good work, and supplier validations, then you would have eliminated 80% of the causes of business problems. The last 20% is left to the individual’s ability to operate the system you have just created. What do we call such a system? A Quality Management System!

For a more in depth example, let’s look at writing articles. In the absence of any policy or process for editing and revising articles, the author might not catch his/her spelling errors or typos (humans err – that’s why newspapers used to have proofreaders).

So when customers read the article — multiply the writer’s two eyes by thousands, maybe millions — the likelihood is great that at least one of them will catch the error.

On the other hand, if there is a process in place where a second set of eyes reads the article and necessary corrections are made (or the central idea is validated) before releasing it, the likelihood of mistakes getting out to the reader are vastly minimized. This doesn’t mean that mistakes won’t happen.

But here too, the system might have a role to play. Is the individual in the right place? If writing is a requirement for the job, was the individual properly screened or trained?

Root Cause Analysis Is the Foundation of Corrective Action

Quality standards and quality tools are there precisely to increase the likelihood of positive outcomes. You may be surprised at how a simple process change can result in a big drop in error rates. But like anything else, the way to improve and be successful at corrective action and root cause analysis is to practice it.

While literature and training are great ways to get started, it is through executing the root cause analysis process that you will learn and improve. And successful corrective action and root cause analysis are critical to achieving continual improvement in your organization. Corrective action is all about finding the root cause.

Looking for Root cause analysis books