How to Get to Best Practices Faster?

It seems like a simple question: How do we get to best practices faster? Bizmanualz offers a wide variety of products and services that can help you achieve this goal.

There are two options to choose from:

- Select a policy and procedure manual from our published products that you want to start with; or

- Start with a gap analysis to determine the what is needed to close the gap between where your processes are now and where you want to go in terms of your goals.

Getting to Best Practices Faster

What best practices do you start with?

Review Your Current Process

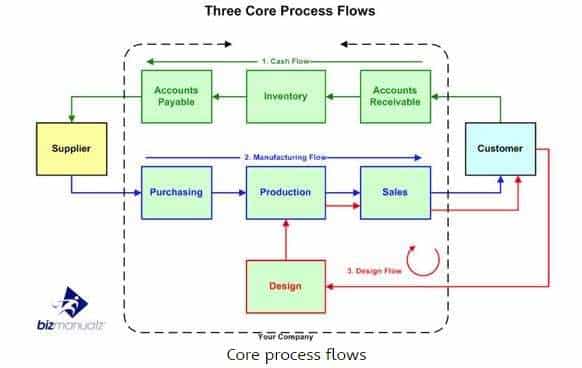

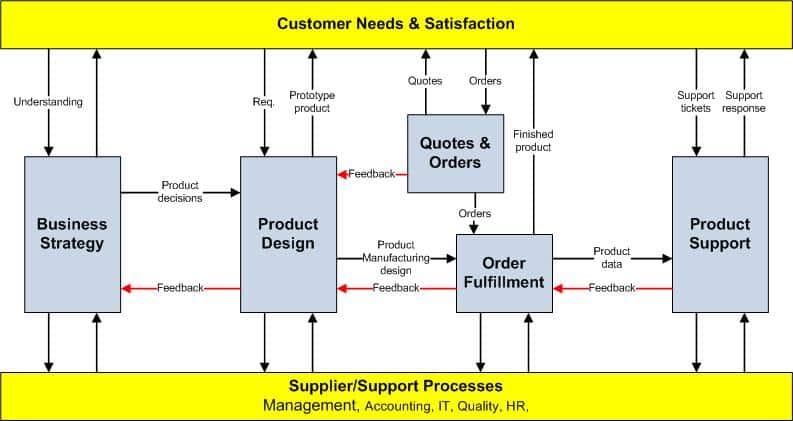

What are you doing now, and what do you want to improve? It is important to start by clarifying processes that are in place now and develop a baseline of the current work process so that you can measure improvement.

Compare Your Current Process to Bizmanualz Best Practice Processes

What did you discover in your process review?

1. Do you have a clearly identified system in place?

Did you find policies and procedures or process maps in place? or did you need policies and procedures examples?

No need to re-create processes when we already have them. You can update your current processes to our set of best practice standard operating procedures, saving you the trouble and expense of researching it yourself. Streamlined processes are simple to understand and easy to implement in microsoft word templates.

2. A system is in place, but it is not stable or consistently working to produce the desired results.

Support processes are necessary for the system to work effectively. Management system support processes include:

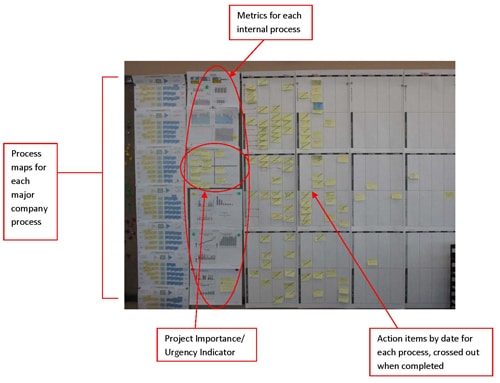

- Visual Management Dashboard

- Frequent Internal Audits

- Regular Management Reviews

- Annual Strategy Planning

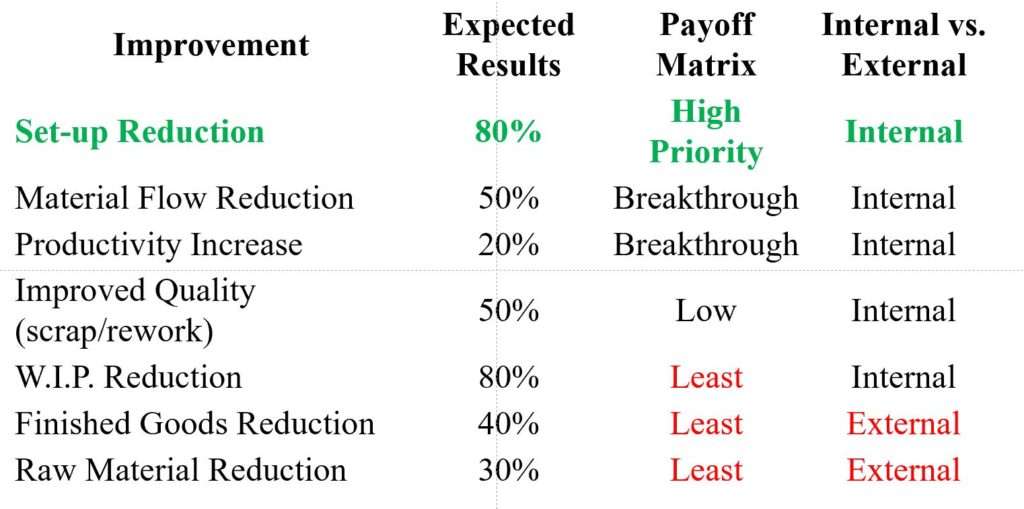

3. A stable system is in place, but there is obvious improvement needed.

There is always improvement possible, no system is perfect. Did you find clear improvement goals in place and is there a roadmap for implementing change. Some example improvement goals:

- Simplify the process so that they will be used by employees;

- Increase the number of sales leads and/or the number of leads converting to sales or other desirable actions, such as signing up for a newsletter, obtaining a sample product, or requesting contact.

- Reduce the number of manufacturing defects or increase quality and customer satisfaction.

- Improve supplier capabilities, supplier relationships, or supply chain quality.

When you lead your improvement project, you can customize the improvement process with our extensive library of best-practice processes to save time and money on research and development. Start with easy incremental improvements that involve and can be sustained by your current staff. Improvements are realistic, achievable, and sustainable so they’re achieved consistently and benefits add up fast.

4. Improvement have been made and improvement are getting more difficult to justify.

At this point, the Cost of Quality should be tracked. As improvement takes hold, further improvements can start to be more difficult to justify on a return on investment (ROI) basis. If this is happening, you need more sophisticated tools, advanced quality methods, and more training in lean Six Sigma to make the waste easier to see.

Where is Your Company on its Journey?

A Bizmanualz quality consultant, trained in advanced ISO lean Six Sigma methods is available to establish and improve your business process. Read about the types of process maps and other tools we can deliver on our site. The do-it-yourself-er can also read about project management tools and use them to manage their own project. Anyone can comb through our manuals-product web site and select individual policies, procedures, and forms manuals or they can choose collections such as the Company Policies and Procedures set!

Leave a Reply