How Do You Drive Change in an Organization?

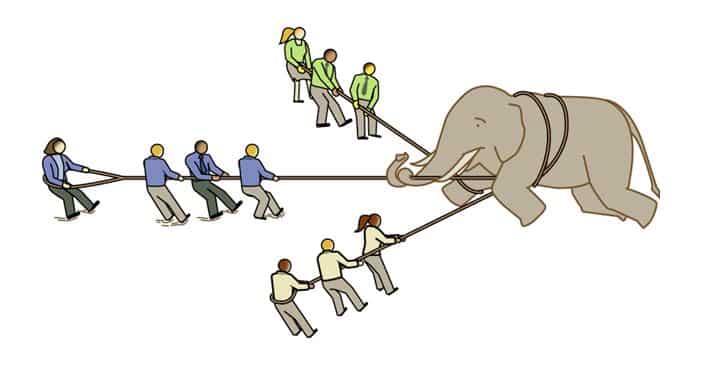

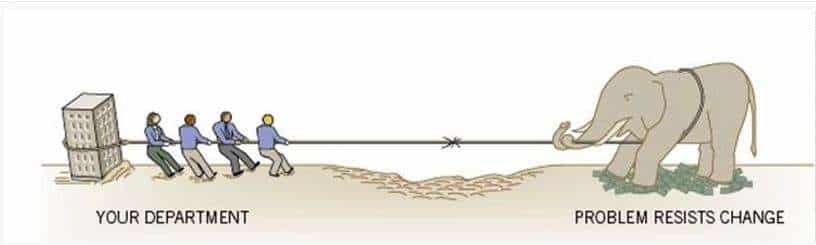

Operational metrics run a a business. In order to achieve your objectives for real process improvement you will need to change the business rules, incentives, and measurements and empower employees to get involved in process of improvement. How do you drive change in an organization?

Driving Change in an Organization

If you want to change the culture of your organization then you will need to change the measurements that your organization uses.

Business Measures as Culture

What you measure creates the culture of your organization. People are generally good and want to do the right thing.

Even when employees are apparently making bad decisions they generally think they are making good decisions. People do things for a reason. If we measure the wrong things we most likely will get the wrong results and make bad decisions in the process.

Business Measures Affect Behavior

Metrics affect behavior in a profound way. In a manufacturing business inventory turns is one of, if not the most critical factors that drives performance. Yet when we go into a business we typically find the plant manager focused on asset utilization instead of inventory turns. What’s going on here?

There is a false belief that in order to generate the highest return on investment; you must keep all of these assets (investments in plant, machines, and labor) working at 100% capacity. Plant manager’s are typically compensated on their ability to achieve the highest asset utilization possible, even if that means a large build up in inventory or keeping the line running while defects are occurring.

Some Measures Encourage Sub-Optimization

What’s really going on is that the plant manager is sub-optimizing by elevating one element in the business, manufacturing, above all other elements, like the cash cycle or quality. The plant manager’s behavior is driven by the metrics used to measure performance. If you’re still wondering how to get buy-in, the next step is changing how the plant manager measures results.

Get Better Return on Assets

To increase your return on assets you only need to focus on those assets that are constraining your manufacturing cycle. Only constraints need to be at 100% utilization, all others can be at something lower than 100%.

People Don’t Create Defects, Systems Do

Systems are made of up of our objectives, metrics, policies and procedures. The management procedures you use make up your management system.

If we set the wrong objectives, use the wrong metrics and document the wrong things, then we will get the wrong results. Yet we have a tendency to blame the people. The great quality leader W. Edwards Deming once said,

“People don’t create defects — systems do”.

Drive Organizational Change

What you measure is what you get, so be careful what you measure. Your measurement system drives the people in your organization. If you want to improve a process then look at what drive the process, not the people, and then change what influences the process.

To reach your goals for actual process improvement, you will need to adjust the business system (policies, procedures, and metrics, as well as empower people to participate in the process.

‘Humans don’t make mistakes – System makes’ . This is the key statement of the article that makes a human resource person like me need to think a lot. If employees play flappy bird games, or eat and drink during working hours and they can freely talk and share, will it improve the operating system?

The employee may have poor judgement, but if the “operating system” allows them to do it, then the operating system has a mistake and needs to be corrected. Corrective action may include improving management follow up, oversight, Key performance indicators, communication, feedback, reporting, role models, training, etc.