Critical Quality Procedures, What are They?

What Critical Quality Procedures do you need? Are you plagued by a tight money supply, a tight job market, stagnating production and a general crisis of confidence. Some of you are going about your business logically, methodically, and with a clear sense of direction and purpose. Will you be making great strides forward in the coming years? Among them are implementing or refining your key quality procedures. Critical quality procedures, what are they?

10 Examples of Critical Quality Procedures

Listed below are 10 examples of critical to quality procedures you should have in place in your quality management system. What are they?

10. Vendor Evaluation

We’ve all outsourced many of our “non-core” functions, but how many of us are guilty of inattentive behavior with respect to our outsourcers (external providers)? You get a little complacent and what happens?

Deadlines start to slip, or substandard product starts to sneak in. Since vendor evaluation is a top quality procedure, now is a good time to evaluate your product and service vendors to see if they’re measuring up to your standards.

9. Document Control

Do you know if your employees are following the same guidelines? If you had to ask an employee to take over another’s duties for the day because of an illness, would that first employee know where to go for information?

Do they have access to the latest version of the procedure? It’s important that you keep your documentation, however critical it is, under control. One easy way to follow this one of the top quality procedures is by using policy management or document compliance management software.

8. Process Monitoring and Measurement

Companies that don’t monitor and measure their performance have no way of knowing for certain if they’re doing better than they were six months or a year ago, or in which direction they’re headed. We can’t improve what we don’t measure.

7. Control of Nonconforming Product

One of the worst things that can happen to your company…worse than finding an error on the production line, worse than finding a nonconformity during inspection…is having a customer find a nonconformity for you. Nothing hurts your company’s reputation worse than a customer finding a poor quality product, getting a late delivery, or finding a billing error in your favor. So, it makes sense that this is one of the top quality procedures.

6. Identification and Traceability

This is one of the biggest issues in food safety. As important as identifying unsafe product and removing it from the food supply chain is tracing the offending product to its source. ISO 22000 already had a clause addressing traceability when ISO developed a new standard, ISO 22005, to address the issue further. Whether you’re in the food business or another line of work, your customers will benefit from improved traceability of your components.

5. Competence, Awareness, and Training

Very few things improve your company’s performance — and reputation — more than a well-trained, capable work force. Ongoing training helps your employees gain self-confidence. This one of the top quality procedures also lets them know how important they are to your success.

4. Customer Satisfaction

4. Customer Satisfaction

Some refer to it as “customer loyalty”; others call it “the customer experience”. Whatever label you give it, your company wants to do more than retain customers. You want your customers telling all their contacts how great you are, how if every supplier was as customer-conscious as you, their business would be exceptional.

3. Control of Records

Your quality records, your accounting records, your sales records — these are the foundation for your company’s success, now and in the future. Barring the invention of a foolproof “crystal ball” app for your smartphone, knowing where you are in relation to where you’ve been and acting on that knowledge to improve your processes are key to your growth. Without adequate recordkeeping, you are flying blind into the future.

2. Internal Auditing

The best way to ensure the effectiveness of your operations and the viability of your organizations is to have your systems — accounting/finance, operations, IT, quality, etc. — audited. You should have a third party, someone with knowledge, experience, and impartiality, periodically audit your systems. In between, you should self-audit your systems to ensure that they’re in compliance, are effectively implemented and maintained, and that they’re achieving the desired results.

And the most important one of the top quality procedures you can implement to improve your quality and performance?

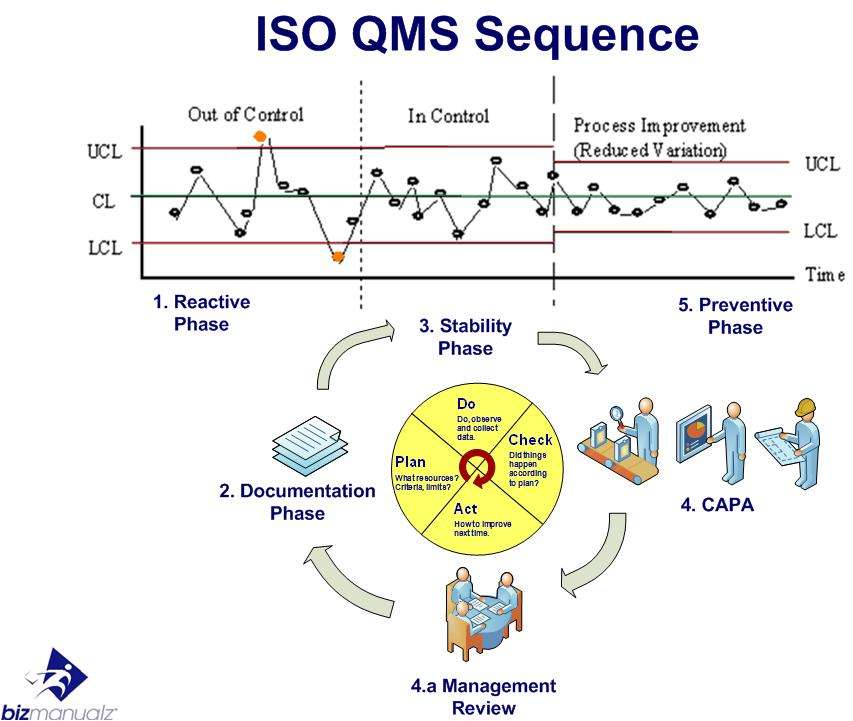

1. Corrective and Preventive Action

It’s a two-way tie for number one. Corrective and preventive actions (CAPA) are intertwined, though they’re not interchangeable. A corrective action is the one you take to ensure that a problem that has occurred does not re-occur or happen again. A preventive action is what you do to prevent, or lessen the likelihood of a potential problem from happening in the first place.

Think of a heart attack: surgery to repair the damaged heart, combined with other measures (improved diet, exercise, etc.), is a corrective action. Regular exercise, a healthy diet, and (when you reach a certain age) regular visits to a cardiologist before you have a heart attack are a preventive action. Before something happens is preventive, after it has happened, is corrective.

The Top 10 Critical Quality Procedures

And, don’t forget what binds these top quality procedures together — a mission, vision, and strategic plan for your firm. What do you think? Are there any procedures you’d add, or take out of this list? Would you put them in a different order?

Leave a Reply