Who Sets Work Instruction Standards?

In today’s fast-paced world, work instructions are key for efficient and effective workplaces. These standards are usually set by industry experts or regulatory bodies and form the basis of operations. Who Sets Work Instruction Standards? Various entities. Professional organizations specialize in a certain field or industry. They bring together experts to create best practices and standards.

Work Instruction Standards are Set by Experts

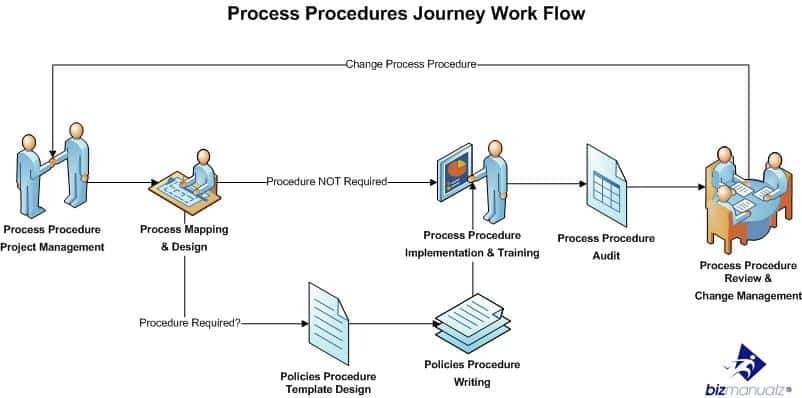

Work instruction standards are set by industry experts and regulatory bodies to ensure consistency, safety, and efficiency. These serve as guidelines for organizations to create processes and procedures that let employees do their tasks right. By following these standards, companies can increase productivity, reduce errors, and hold quality. Plus, they help ensure compliance with legal and ethical requirements.

Organizations typically collaborate with subject matter experts to establish procedures and work instructions standards. These experts bring their insight into the best practices and industry benchmarks related to a task or process.

They help create standardized methods for repeatable operations. By using diverse perspectives, organizations can make comprehensive and strong work instruction standards for different scenarios.

Government agencies set standards in regulated industries like healthcare, aviation, and finance. This ensures compliance and safety. Companies can also set their own standards. This lets them tailor guidelines that fit their structure, processes, and goals.

Regulatory bodies are key players in setting work instruction standards across industries. They make sure workers, consumers, and the environment are safe. They develop regulations and guidelines based on research, data analysis, and stakeholder inputs. Companies have to abide by these standards to operate in the sector.

Factors to consider:

- Involve subject matter experts for comprehensive coverage. Leverage their expertise for a holistic set of guidelines.

- Regularly review and revise. Stay updated with tools, techniques, regulations, and safety protocols. Ask employees for feedback to identify areas for improvement.

- Clearly communicate standards. Provide training sessions or workshops. Incorporate visual aids to enhance comprehension.

To make work instruction standards better, organizations can:

- Periodically Review: Check if the standards are up-to-date with changing technologies, regulations, and industry trends.

- Get Employee Feedback: Ask staff members for input to identify areas for improvement.

- Provide Training: Give regular training sessions so employees know the latest techniques and changes.

- Industry Collaboration: Exchange best practices and promote innovation by teaming up with other industry organizations.

These suggestions help organizations ensure work instruction standards are always improving and reflect industry advancements. This leads to improved efficiency, productivity, and success for businesses.

Industry-specific Organizations and Regulatory Bodies

Let’s explore some examples of industry-specific organizations and regulatory bodies. Like the Food and Drug Administration (FDA). They make sure food is safe and drugs regulated in the US. The Occupational Safety and Health Administration (OSHA) enforces workplace safety regulations. and the Financial Industry Regulatory Authority (FINRA) oversees financial transactions.

Then there is the International Organization for Standardization (ISO). They develop standards for products to be reliable and of high quality. They cover various industries, like manufacturing and healthcare.

Industry-specific organizations and regulatory bodies do more than just set standards. They educate businesses about best practice. They provide training programs and inspections. They collaborate with government agencies to shape consumer protection policies.

Take the Institute of Electrical and Electronics Engineers (IEEE) as and example. They set standards for tech-based industries. In 2000s, they developed Wi-Fi standards. This enabled devices from different manufacturers to communicate. It revolutionized wireless technology!

Here’s and example of why standards are important. In a manufacturing plant, there was no standard for operating a machine. Each operator did it differently. This caused inconsistencies and breakdowns. So, they invested in clear instructions. This improved productivity, reduced downtime, and ensured high-quality output.

Company-level standards are where everyone agrees on how work should be done. Until someone figures out a faster, lazier way.

Company-level Standards

Company-level standards for work instructions are set to ensure consistency and efficiency in operations. Guidelines and procedures must be followed precisely. This streamlines processes and reduces errors, leading to improved productivity.

Let’s look at the key aspects of these standards:

- Format: Clear and concise instructions, easy to understand.

- Content: Necessary steps, precautions, and relevant info must be included.

- Accessibility: Digitally or physically available for all employees.

- Review: Regular reviews and updates are essential.

- Training: Employees must understand and follow the standards.

These standards create uniformity and a smoother workflow. They may differ depending on industry and organization. To facilitate understanding, consider using visual aids like diagrams and images.

Company-level standards help optimize processes and maintain quality. It’s like having a GPS for your team – without it, they’re j

ust wandering around lost in a corn maze with no way out!

Best Practices for Setting and Maintaining Work Instruction Standards

Take action now! Increase productivity, improve training outcomes, and streamline processes by implementing best practices today.

- Ensure clear communication by using simple language avoiding jargon or tech terms.

- Create a consistent format, like numbering or bullet points.

- Update work instructions regularly.

- Make the layout user-friendly with headings, subheadings, and visuals.

- Give employees a feedback mechanism to provide input.

- Tailor these practices to your company’s culture, industry, and workforce.

Still don’t know who sets work instruction standards? Just like my GPS can’t figure out how to get me to the right destination.

Setting Work Instruction Standards

Who sets work instruction standards? This depends on the industry and organization. Regulatory bodies and industry best practices play a role. Plus, individual companies often create their own standards.

Frequently Asked Questions

FAQ: Who sets work instruction standards?

Q: What are work instruction standards?

A: Work instruction standards are guidelines or criteria that dictate the quality, format, and content of work instructions in a particular industry or organization.

Q: Who is responsible for setting work instruction standards?

A: Work instruction standards are typically established by industry associations, regulatory bodies, or internal quality management teams within and organization.

Q: Why are work instruction standards important?

A: Work instruction standards ensure consistency and uniformity in how tasks are performed, enhance safety, promote efficiency, and facilitate effective communication among employees.

Q: How often do work instruction standards change?

A: The frequency of changes in work instruction standards varies depending on the industry, technological advancements, regulatory requirements, and internal process improvements.

Q: Can and organization customize work instruction standards?

A: Yes, organizations can customize work instruction standards to meet their specific needs as long as they comply with any mandatory regulations or requirements set by external entities.

Q: How can employees stay updated on work instruction standards?

A: Employees can stay updated on work instruction standards through regular training sessions, internal communication channels, industry publications, and engagement with regulatory bodies or industry associations.

Leave a Reply