What are Examples of a Lean Company?

A lot of companies are implementing a lean daily management system to develop a lean competitive advantage, but then question if what they are doing is really lean. Some people think applying lean is like applying six sigma. But, Lean is not like six sigma. So how do you know when you have gotten lean? In other words, what are examples of a lean company? Here are ten simple ways to tell how lean you really are.

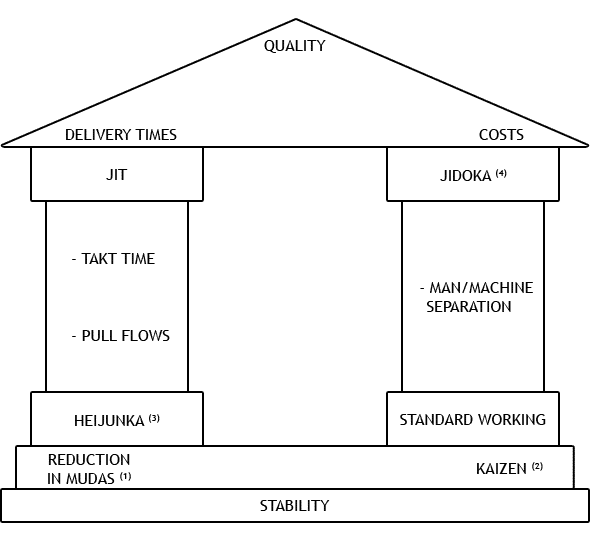

Lean Production Systems

In the book “The Machine That Changed the World”, they used the term lean to describe how Toyota was managing their company. Their production system flowed, problems were quickly addressed, and they used less inventory, it was lean. So what does lean look like?

In the book “The Machine That Changed the World”, they used the term lean to describe how Toyota was managing their company. Their production system flowed, problems were quickly addressed, and they used less inventory, it was lean. So what does lean look like?

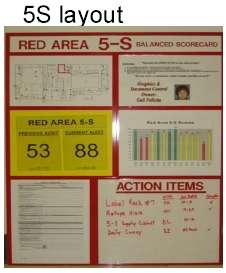

1. Clean and Orderly Work Areas (5S)

Most companies start getting lean by implementing 5S, a system of sorting, setting in order, shining (cleaning), standardizing, and sustaining. For some, this sounds like cleaning work areas. A lean system has clean work areas, but clean work cells by themselves are not lean.

A lean work cell contains ONLY what you need. Extra materials are removed and required materials are clearly marked and have a place.

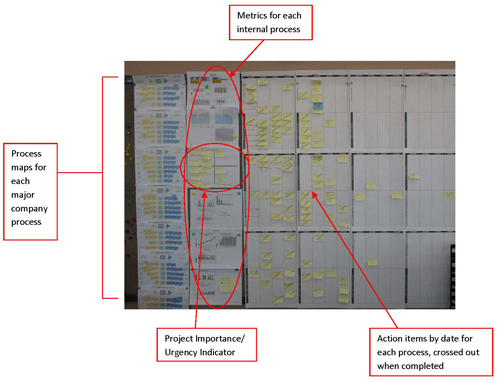

2. Visual Production Plans and Instructions

When you look inside a company with an effective production system you will see work areas labeled with printed signs, the production flow is obvious, work cells are close together with clearly marked hourly production goals. A lean company is well organized with balanced production flows.

3. Visible Equipment Status (Andon)

3. Visible Equipment Status (Andon)

Andon is a Japanese word, which means “lantern?” or “lamp.” Andon lights (red, yellow, green stoplights) are common on production equipment, which are used to indicate if machines are running (green), are stopped (red) or about to run out of material or need help (yellow).

Some machines come with Andon lights, but those lights are of little help if they are not used. Andon lights are signals that help your lean system flow.

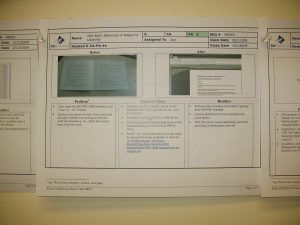

4. Well-Defined Defect Occurrences

Standard work or policies and procedures, should define what defects are for that process and how to handle them. Defects must be recorded and corrected if you are to eliminate them from re-occurrence. A lean daily management system has a well-defined method for defect response. They are not ignored.

5. Little Work in Process (WIP) Inventory

Just in Time (JIT) means only the materials needed for the next job or process step are arriving for processing. In other words, no large batches of standing material, no material handling of next weeks jobs, and no defective materials awaiting rework. JIT systems utilize lean accounting methods.

6. Streamlined Material Handling

To eliminate work in process you need streamlined material handling, which means work cells close enough to each other that one cell can easily hand the part to the next cell. Work cells are balanced so that they are never waiting long for that next part, and materials are choke-released into the production stream at predefined takt time based intervals.

7. Clearly Marked Reorder Levels (Kanban)

Kanban is a Japanese word which means signal so a Kanban based inventory system is based on clearly marked purchasing reorder signals. The reorder point is based on the materials usage to support the predetermined takt time that your system is balanced to. If you have not balanced your system to a takt time then you are not very lean yet.

8. Well-Maintained Equipment (TPM)

Total Productive Maintenance (TPM) is a system of attending to the maintenance needs of your equipment so that your machines do not break down in the middle of production. If you are maintaining your equipment on a schedule and repairing them before they breakdown, then you’re following the steps towards a lean system.

9. Stress Free Employees

A lean daily management system show great respect for workers. A workers time is not wasted. Processes are well-defined with clear error-proofing (Poke Yoke) implemented ahead of time. Workers are encouraged to “Stop?” the system in order to fix defects as they occur. A worker’s input is encouraged as a great source of process improvement ideas. A lean daily management system empowers workers to increase productivity through lean thinking.

10. Noticeable Signs of Improvement

A lean daily management system is under a constant state of front-line driven improvements. Employees are always working on correcting defects from occurring, maintaining their work cells with 5S, performing preventive maintenance, and finding opportunities for improvement.

Companies in Japan get more than 200 times the number of front-line ideas and more of those ideas are implemented, than the average company in the United Stated. Process improvements in a lean daily management system are driven by the employees and NOT management.

Examples of a Lean Company

Lean looks like a well run plant. It looks clean, orderly, visual, and a lot like common sense. To learn more about using process improvement programs for your organization, attend the next Implementing Lean Thinking class. Call for information on having your own private in-house classes today.

When it comes to implementing lean, we’re often talking about reducing waste through establishing efficient and robust business processes, standardizing each task, and establishing the skills to solve problems to constantly learn and improve. Basically, those factors must be considered from the beginning of the business. There will possibly be little in the way of formal business processes as the business is more likely to be run by a small number of individuals who fulfill numerous functions. I recommend reading more lean books.