What Is an ISO 9001 Gap Analysis?

If you are thinking of preparing an ISO 9001 Quality Management System (QMS) then where do you start? We start with a Gap Analysis to determine the gap between your current management system and an ISO 9000 conforming QMS.

What is meant by Gap Analysis?

What is meant by Gap Analysis?

A Gap Analysis is used to assess an organizations readiness and its resources for building a management system like an ISO 9001 QMS. It also provides us with the data to develop a project plan for ISO implementation.

What is the Scope of an ISO 9001 Gap Analysis?

Your QMS scope applies to what product lines, ISO 9001 clauses, and facilities that you are planning on registering to ISO 9001. You do not have to register every product line. At Bizmanualz, we are preparing for our own registration audit that will include our manual products, consulting and training services. That means both our products and services will be included in the registration process.

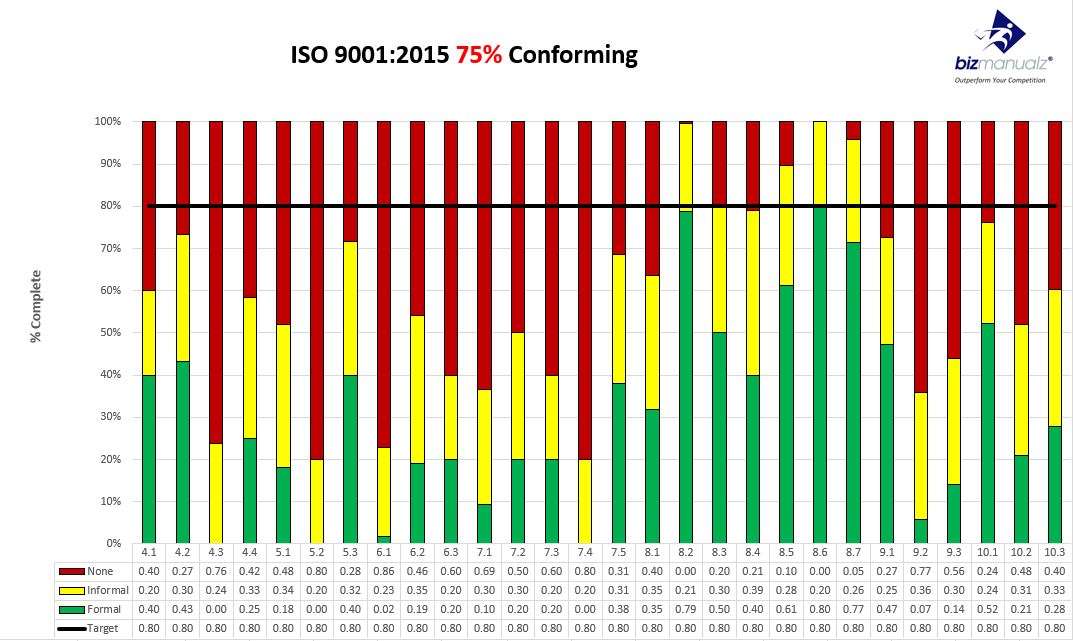

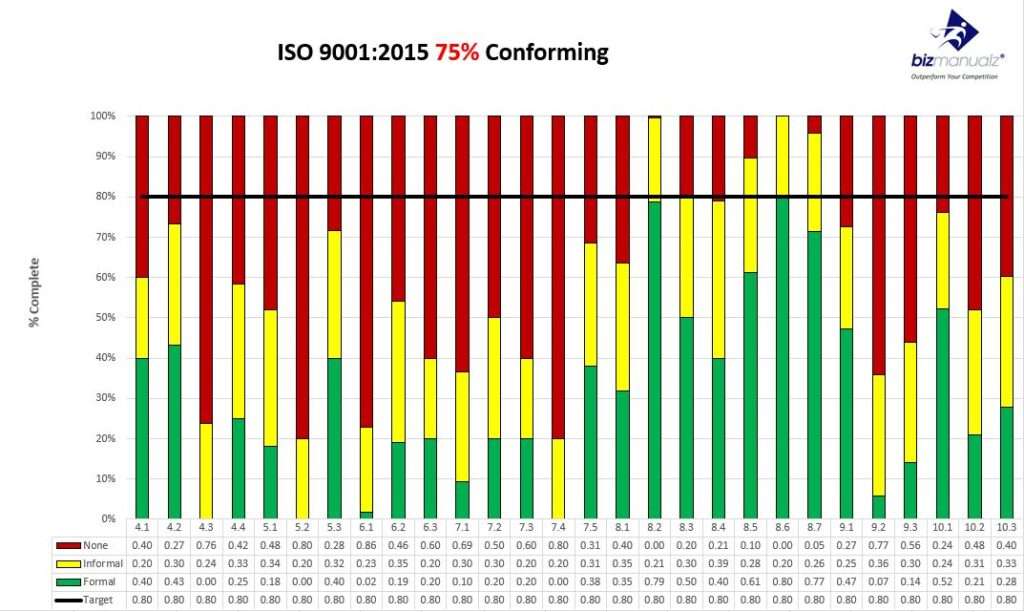

To define the scope within the Gap Analysis we look at what processes need to be included and described within the free IOS 9001 2015 procedures. The output is a draft process map. Next we examine each clause of the ISO 9001 standard. There are 136 “shall” statements that we count to see which ones apply and how an organization may be conforming. These shall statements include 24 required documented information, Quality assurance policy statement and procedures, and many process requirements that must be fulfilled, but there is a lot of leeway on how you might fulfill those requirements.

For example, collecting customer feedback is a required process or that processes must be measured is a requirement, but how you do this is totally up to you. You do not have to write a procedure for this or keep a record of measurements. As odd as this sounds you have to free your mind of paper solutions and think of visual or electronic methods that could accomplish this.

The output of the ISO Quality “shall” count is a histogram that shows you how your organization stacks up, clause by clause, and a list of possible exclusions of areas within clause eight that may not apply. Each exclusion claimed will require a proper justification within the Quality manual or scope document. In the Gap Analysis phase we should be able to give you an idea on possible exclusions.

Assessment Through ISO Gap Analysis

A Bizmanualz ISO Gap Analysis assesses the current state of the organization (situation analysis) and produce a baseline for comparison to the target goals and objectives. For example, implementing an ISO 9001 QMS in 30 days is more effort than implementing an effective management system in 180 days.

The Bizmanualz Gap Analysis results in an engagement plan that identifies the gaps between the baseline and the target goals, the specific action steps and the resources required to achieve the project objectives (see Engagement Plan below).

The Bizmanualz Gap Analysis starts at $2,500.00 for the first two days (most Bizmanualz Gap Analysis are completed within two days).

Upon receipt of a Purchase Order, Bizmanualz, Inc. will arrange a mutually convenient date for the Bizmanualz Gap Analysis to be performed. During this assignment, Bizmanualz proposes two review meetings one at the outset, and the other isoqmsat the completion or delivery to review the effectiveness of the project and deliverables. The analysis itself consists of five core activities.

How to Plan the Gap Analysis?

Pre-planning activity between the organization and ISO Consultant. The ISO Consultant will contact you to obtain background information used to become familiar with the engagement. Pre-planning occurs prior to the onsite visit and may includes the collection of various documents, such as:

- Business Summary. An organization profile describing the business activities, locations, and number of employees at each location.

- Target Engagement Objectives. Current scope, goals and objectives description for the follow-on engagement.

- Org Chart. Current organization structure.

- Job Descriptions. Employee data by function.

- Employee Handbook. Current Personnel Manual.

- Support Contacts. Contact details identifying the personnel available to support the Gap Analysis.

- Organization Surveys. Completion of management and employee surveys.

- Management Manual or Data. Management Manual, Policies, Procedures, Contracts or agreements, and Forms that make up the current Management System.

- Software Review. An overview of the software tools used to manage employee data, control organizational documents, or management data.

- Financial Statements. The last five years of financial statements summarizing the company’s performance.

Gap Analysis Introductory Meeting

An introductory meeting with top management, facilitated by the ISO Consultant, outlining the methodology and deliverables. The introductory meeting will occur on the first morning of the engagement.

The aim of this meeting is to agree on the overall delivery plan and to review and determine the full requirements and scope of the project, allocate tasks and analyse and mitigate any project risks. There will also be an opportunity for questions and answers.

Gap Analysis Data Gathering

Data gathering activities involve gathering interviews, performing data analysis, and observations with a cross-section of the organization’s personnel. After the introductory meeting is concluded, the Principal Consultant will spend the rest of the first day, and/or second day, collecting the data for the Gap Analysis Report, similar to conducting an internal audit. In fact, the ISO 9001 Gap Analysis is an audit or assessment of the QMS where each finding becomes an action item within the implementation plan. Audit finding are gaps found between operational practices and the ISO 9001 standard.

Gap Analysis Report

Next, gather together the data and analyze the gaps found and determine the level of effort to implement the ISO QMS. Production and distribution of the Gap Analysis Report and QMS Project Plan is the output of these phase. The ISO Consultant will produce a detailed report that will be delivered to you, The Client, within five business days after the conclusion of data gathering.

Gap Analysis Concluding Meeting

The Gap Analysis ends with a concluding meeting with top management and the ISO Consultant. The ISO Consultant will lead a presentation and discussion of the Gap Analysis Report findings and recommendations.

The rest of the afternoon will be spent presenting the findings, answering questions about the findings, and discussing the implementation issues including agreement and finalization of the Project Plan, resources, and dates.

Inevitably, during the development of proposed solutions, new requirements evolve. These requirements can either be listed and considered as part of a separate follow-on project or discussed and treated by an “exception” mechanism, outlining the work involved, the timing and any changes to the overall schedules and the costs involved.

After the ISO 9001 Gap Analysis

With the Gap Analysis complete, we write up what we saw and deliver to you a draft process map, scope with exclusions, a histogram that lists your conformance by clause and a set of implementation milestones to meet your target date. An ISO Gap Analysis is basically a full systems audit but instead of audit findings you get consulting advice on how ready your organization is for ISO 9001. If you are thinking of preparing an ISO 9001 Quality Management System, then an ISO Gap Analysis will provide the answers to your scope, budget, and implementation questions that management will be asking.

Leave a Reply