Reduce Downtime by Writing Standard Operating Procedures

In today’s fast-paced business world, downtime can be a major setback. Whether it’s due to equipment malfunctions, employee errors, or unforeseen circumstances, every minute of downtime can result in lost productivity, revenue, and customer satisfaction. But what if there was a way to minimize downtime and keep your operations running smoothly? Enter standard operating procedures (SOPs). In this blog post, we’ll explore how writing SOPs can help you reduce downtime and keep your business on track.

Why Downtime Matters

Downtime is more than just an inconvenience – it can have serious consequences for your business. Every minute that your operations are offline represents a loss of potential revenue and productivity. Downtime can also damage your reputation and erode customer trust, leading to long-term consequences for your business. That’s why it’s crucial to take proactive steps to minimize downtime wherever possible.

The Role of Standard Operating Procedures

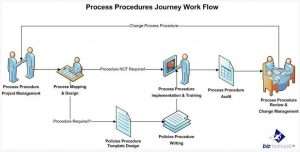

Standard operating procedures (SOPs) are documented guidelines that outline the steps to be followed for specific tasks or processes within your organization. SOPs provide clear instructions, best practices, and protocols for carrying out routine activities, ensuring consistency, efficiency, and quality in your operations. By documenting your procedures in SOPs, you provide employees with a roadmap to follow, reducing the likelihood of errors, delays, and downtime.

Guide to Writing Standard Operating Procedures to Reduce Downtime

Writing standard operating procedures to reduce downtime may not be as elusive as one might think. The tool used in creating these standards and designating each actor’s role is known as Standard Operating Procedures (SOP). This article analyzes the various means of achieving the best possible outcomes while drafting an SOP.

Imagine your business/organization running on the same principles as, say, the engine of an automobile. This means that different intricate parts would be synchronized to result in the desired outcome. For each part to function maximally, there has to be set down standard guidelines regarding the path it is to follow, its functions, etc.

Really, there is hardly any need to imagine your organization running this way because every firm has different parts working in concert in a vast majority of cases. This makes it imperative to delineate functions and roles in a job description. When the roles are described effectively, the same results will be achieved over time.

This is especially important for organizations that place a premium on standardizations. Employees and members of the organization are now allowed to engage in trial and error. There is an anticipated process for each role resulting in a standardized product or outcome.

What are Standard Operating Procedures?

Before getting into the main gist of the writing guidelines to follow in drafting this all-important document, it is necessary to have a fair idea of what it means.

A Standard Operating Procedure (also known as SOP) is a process document that describes how an operator is to carry out any given task. In crafting an SOP, it is important to pay attention to the purpose of the operation, the materials and process needed, as well as the processes for the maintenance of shut down of the system.

It is crucial to bear in mind that an SOP is different from procedural guidelines or work instructions. The former provides in-depth, step-by-step processes that team members and employees must follow. Its focus is on process and outcome. Thus, imagine an SOP to be a document that shows the possibility of moving from Point A to Point B, with the points referring to the starting point of the tasks and the outcome, respectively.

The SOP ensures that all employees ply the designated routes while carrying out their tasks. This helps in the management of expectations and the prediction of outcomes. It also gives room for the running of controlled experiments. When consistent processes are followed, it would be easy to tell how changing certain processes could impact outcomes.

It would also inform the organization about steps to take in training employees for the best routes to take in predicting outcomes. Thus, if a process works and another doesn’t, the organization can then choose and improve on the one that works while jettisoning others.

An SOP also ensures that all team members are on the same page. It eliminates lags and primes the organization to make the best of every given process.

How SOPs Reduce Downtime

- Consistency and Clarity: SOPs ensure that everyone involved in a process understands their role and responsibilities. With clear guidelines in place, employees can perform their tasks consistently and efficiently, reducing the risk of errors and downtime.

- Training and Onboarding: SOPs serve as valuable training tools for new employees, enabling them to quickly get up to speed and perform their duties effectively. By providing structured guidance from the outset, you can minimize the learning curve and ensure that new hires contribute to your operations with minimal disruption.

- Problem Resolution: When issues arise, SOPs provide a framework for troubleshooting and problem resolution. Employees can refer to the relevant SOPs to identify potential solutions and take appropriate action, minimizing the impact of downtime and helping to restore operations quickly.

- Preventive Maintenance: SOPs can also include procedures for preventive maintenance, helping you identify and address potential issues before they escalate into downtime-causing problems. By implementing regular maintenance schedules and inspections, you can keep your equipment and systems running smoothly and minimize the risk of unexpected downtime.

- Continuous Improvement: SOPs are not set in stone – they can be updated and refined over time to reflect changes in technology, processes, or best practices. By regularly reviewing and updating your SOPs, you can identify opportunities for optimization and innovation, further reducing the risk of downtime and improving overall efficiency.

Writing SOPs to Reduce Downtime

It is possible to write policies and procedures to achieve various aims. In each scenario, the intention of the writer will be reflected in the document’s language. This, even though general templates for drafting SOPs abound, in particular instances, you will have to tweak the document to serve your aim better.

Considering our discussion, your intention of writing an SOP will be to eliminate downtime. In the world of manufacturing (where the term is mostly used), downtime refers to a loss of machinery and capital due to various factors. It refers to situations where employees’ actions or inactions contribute to the company’s loss while time is being wasted.

In looking to write an SOP to eliminate downtime, here are some areas of lean waste that you should be geared towards:

Overproduction

It is a dangerous state of affairs if team members do not realize when to stop production. Overproduction occurs when the supply of the goods (or services) clearly exceeds the demands for them and you end up with excess finished goods inventory that is stored for future use. It becomes most apparent when there is inaccurate data to analyze customer demands, poorly applied automation, and poor forecasts.

Overproduction is bad for business. Hence, managers and team leaders have to eliminate it as early as possible. If overproduction is not handled, crucial resources for other projects could be wasted on just one project.

Eliminate Defects

Defects are some of the most common causes of downtime. They vary, given the nature of the organization’s business or activities. For instance, what constitutes a defect for a local diner would be different for a car repair facility.

Thus, while writing an SOP, it is important to consider the possible defects the team could have to grapple with. Create an SOP that seeks, as far as possible, to eliminate these defects when they arise. There are some standard documents the help writing policies and procedures like an FMEA or control plan.

Minimize Delays and Wait Time

Process delays can be frustrating and it can also cost you clients. This is because a lot of customers, especially first-time ones, may not be patient enough to wait out any lags in the process. Of course, delays may just be outside of your immediate control.

A piece of machinery may break down, or a team member may fall ill. In these instances, delays may erupt. However, you can take crucial steps to eliminate or control these delays. While creating the SOP, engineer steps that would take out any lags, especially when transitioning between processes.

Eliminate Needless Motion

This is a stretch of the discussion above. Motion waste refers to the extra processes and steps which may not be needed when carrying out a task. You may often be unable to immediately note motion waste because it could be enmeshed in the process. Hence, while writing the SOP, carefully comb through the steps you apply. Eliminate the ones that add nothing to the eventual outcome. You can also combine any that you think can work best as a pair.

Writing Standard Operating Procedures to Reduce Downtime

Downtime is a costly and disruptive issue for any business, but it doesn’t have to be inevitable. By investing in standard operating procedures (SOPs) and documenting your processes effectively, you can minimize downtime, improve productivity, and keep your operations running smoothly. From providing clear guidance to employees to facilitating problem resolution and preventive maintenance, SOPs play a crucial role in reducing downtime and ensuring the continued success of your business.

Writing a Standard Operating Procedure is the best way to predict outcomes. You will be maximizing your team’s strengths and eliminating wastes in one stroke.

However, while looking to eliminate downtime, you may need to pay a little more attention to what you include and what you leave out. Following the steps above, you should be able to pinpoint the exact locations to pay attention to when writing your SOP.

Bio: Sandra Manson is a passionate journalist who has been contributing to major media publications. She enjoys writing about human psychology and lifestyle, as well as the tech industry. Sandra also runs her blog mailorderbridesadvisor.com where she covers topics of great interest in modern society.

Leave a Reply