Why process improvement is important

Process improvement is important for change and survival. Does anybody want to change? Your corporate culture represents your readiness and willingness to change before processes can improve. How well does your organization accept new ideas for development and process improvement? How much risk can your organization handle? Why is process improvement important? Moreover, how does your leadership promote change? These simple questions provide the answers to your readiness and willingness for real change management to occur.Your survival may depend on it.

How Do You Sell Process Improvement?

New ideas follow an adoption curve. A new idea is introduced and then grows rapidly through to maturity and eventually enters decline. Organizations dedicated to process improvement (i.e. Toyota, GE) have very short Idea Adoption Cycles and are able to improve quickly.

What drives the Idea Adoption Cycle? There are two primary motivators, process improvement aspiration and desperation. Every organization uses one or the other to sell new process improvement ideas. Which one does your organization choose? Unfortunately for most of us, it is usually desperation over process improvement aspiration.

Fear is a powerful motivator, used by many to get change started. Threats like “The company is going out of business unless we change!” or “You will lose your job unless you change!” are examples of fear motivating change. However, unless the organization is self-motivated to change, the result will be temporary, at best.

Are you solving problems or improving the process? How long will it be before things improve and the organization goes back to the old habits? You know the story: profits improve, fear subsides, and complacency sets in. Sound like your situation?

Process improvement aspiration is the key. In order to create the self-motivation we need to paint a strategic picture of a more positive future. We need everyone’s buy-in. We need the organization to want to improve, to aspire to greater things. Without the organization’s buy-in we will have an empty process improvement program with limited effectiveness and very long Idea Adoption Cycles.

How do we shorten the Idea Adoption Cycle? We need to grease the wheels of change by reducing new idea risk.

How Much Risk Can Your Organization Handle?

Risk is the possibility of loss. It is a function of the likelihood of loss and the impact of that loss, should it occur. Everybody is risk averse to some extent: we all know those situations where we prefer to keep what we have (know now) rather than take a chance on gaining something we do not have (do not know now). We have discussed how desperation reduces short-term risk – change or else, what do you have to lose! But, how do you reduce the risk of new ideas with process improvement aspiration?

Fear comes from what we do not know. Confidence comes from what we know. Desperation is the result of a fearful organization decaying from the status quo, whereas aspiration results from a confident organization built through education and effective training. W. Edwards Deming believed that knowledge is essential for creating value in a system, while fear is destructive to both the system and to individuals. We need to neutralize fear of the unknown with confidence from education of the known.

If you let fear govern your organization, then change will simply not take place because of the associated risk of failure, thus leading to desperate acts to regain motion. On the other hand, if you let process improvement aspiration guide your organization, then change will not only take place, but you will be creating a self-motivated, self-learning organization that will desire to continuously improve, which is what you really want.

How Does Your Leadership Promote Change?

Leadership must clearly understand and communicate the motivation for change – they must get buy-in. Are your visions and goals clearly communicated and understood by everyone in the organization? Ask yourself, “What are we in business to do? How do we get it done?”

The answers from everyone should be clear, consistent, and concise. Without such clarity of purpose, your organization will not be able to transform objectives into results, which means it is not ready for change.

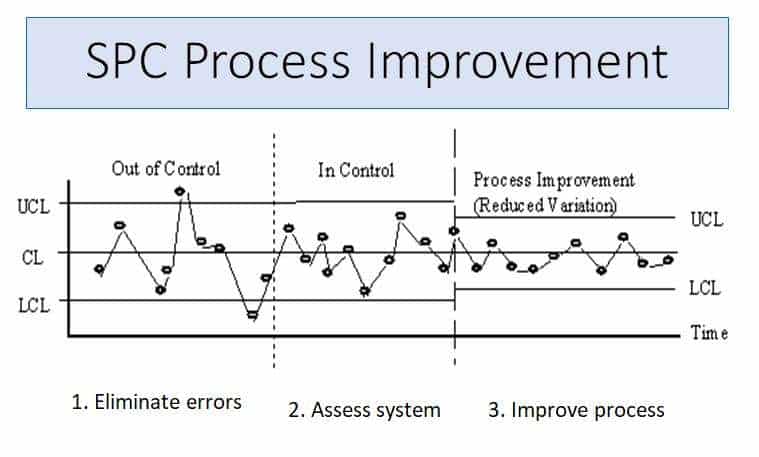

Leaders must determine whether the organization is ready for the disruption and uncertainty that is about to follow. No change management program occurs without some bumps along the way. In fact, you will often time see things get worse before they get better. That does not mean the management system is not working it just means that there is a lot of garbage in the system that must be worked out first. It is all a part of becoming a better manager.

In addition, leaders must provide the right incentives to empower employees: rewarding new ideas, providing resources for training, and allowing time for the organization to learn together and make mistakes. Learning occurs through trial and error until you get it right. And, even when you do get it right, you will find that everyone else has to get it right at the same time. The whole organization has to come together at the right time and place.

Deming was especially concerned with effective uses of motivation, and emphasized the motivating power of joy, satisfaction, and pride that occurs when everyone contributes to an effective system. He noted how many typical employee reward programs are contrary to appreciation for a system, and hurt, rather than help, morale. He also was concerned about organizational cultures based on fear, which is destructive to both the system and to individuals.

What is Business Process Improvement?

Process improvement is doing the impossible. It was not long ago that people considered flying impossible. Yet today we regularly fly 100-ton aircraft full of 200 people or more. So what changed? What is regularly impossible in one paradigm may be considered more than possible, in fact easy in another paradigm. What changed is the paradigm.

To change your performance you must first change your thinking. There is no other way. Quality tools like lean thinking, six sigma, or theory of constraints are virtually worthless if you have not addressed the organization’s belief system. Oh sure you can go ahead and implement the tools but if the organization does not believe in quality then you will not be able to sustain the changes needed for success.

If you believe it then you will see it. Once you see it, you will see it everywhere around you too. Then, anything is possible because reality is a story your brain and the world work out together.

Think like a magician. Using lean thinking quality tools you can go into any organization and make inventory or time delays disappear. Using six sigma you can astonish customers with reductions in process variances that were never thought possible. Using theory of constraints you will find profits in processes that you didn’t know were there. Yes, you too can do the impossible because you know the secrets to the magic of quality.

Once you know how the quality trick is done then you will realize that the impossible is just an illusion. The real issue is getting others to see the impossible as an illusion or how the trick is done in order to see past the illusion. Nothing is impossible once you learn the magic of quality.

There are a lot of different process improvement programs on the market today and everyone has their favorite. I am sure you recognize a few of these programs. Have you ever wondered what the difference is between each of these? There are many consultants in the market that are advocating the use of one of these improvement methods to solve all of your organizational problems. But will all of these work in any situation? Or, are there specific situations that are better suited for a particular approach?

Leave a Reply