What Does The SOP Acronym Mean?

Are you confused by acronyms like SOP used in the workplace? If so, you’re not alone. This article dives into the meaning of SOP – Standard Operating Procedure – and how it can be used to benefit you and your business. Don’t miss out on this opportunity to gain valuable insight into the world of SOPs! What Does The SOP Acronym Mean?

Definition of SOP

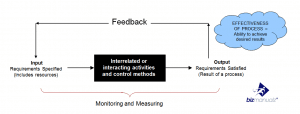

To put it simply, an Standard Operating Procedure (SOP) is a written document that details the exact steps required to complete a specific task or process. This document serves as a guideline that employees can follow to ensure that their work is consistent and of a high quality. In essence, SOPs provide a blueprint for business operations, outlining the most efficient and effective ways to accomplish various tasks.

For example, in a manufacturing setting, an SOP might outline the specific steps required to assemble a particular product. This could include information on the necessary tools and equipment, the order in which components should be assembled, and any quality control checks that need to be performed along the way. By following this SOP, employees can ensure that each product is assembled in the same way, every time, resulting in a consistent and high-quality end product.

Importance of SOP in Business

So, why is an SOP so important in business operations? There are several reasons why this tool is essential:

- Consistency: SOPs ensure that all employees perform tasks in the same way every time, eliminating variability and increasing efficiency. This is particularly important in industries where even small variations in processes can have a significant impact on the end product or service.

- Quality: By providing step-by-step instructions, SOPs help to ensure that work is completed to a high standard and meets all necessary requirements. This can be especially important in industries where safety or regulatory compliance is a concern.

- Compliance: SOPs are often used in highly regulated industries, such as healthcare and finance, to ensure that all work is performed in accordance with relevant regulations and laws. By following an SOP, employees can help to ensure that their work is legal and ethical.

Overall, SOPs help to create a culture of consistency, quality, and compliance within an organization. By providing clear guidelines for how work should be performed, SOPs can help to improve efficiency, reduce errors, and increase customer satisfaction.

Common Industries Using SOPs

SOPs can be applied across a broad range of industries, but they are particularly common in those that require highly standardized processes. Here are just a few examples of industries that commonly use SOPs:

- Manufacturing: SOPs are used to ensure that products are assembled consistently and to a high standard.

- Healthcare: SOPs are used to ensure that medical procedures are performed safely and in compliance with relevant regulations.

- Finance: SOPs are used to ensure that financial transactions are processed accurately and in compliance with relevant regulations.

- Food service: SOPs are used to ensure that food is prepared safely and in compliance with relevant health and safety regulations.

- Transportation: SOPs are used to ensure that vehicles are maintained and operated safely, and that shipments are handled correctly.

Overall, SOPs are an essential tool for any organization that values consistency, quality, and compliance. By providing clear guidelines for how work should be performed, SOPs can help to improve efficiency, reduce errors, and increase customer satisfaction.

What Does SOP Stand for in the Workplace?

.jpg)

SOP, an acronym of Standard Operating Procedure, is a detailed written document that outlines the workflow and actions to be taken in specific routine tasks in a workplace. These outlined guidelines are structured by a set of rules that every employee must follow to ensure smooth day-to-day business operations.

In essence, SOPs can be applied to various areas of the business as they provide clarity and consistency across different departments and functions. Therefore, organizations must implement effective SOPs to minimize errors and increase work efficiency.

Effective SOP implementation requires ongoing management review, evaluation and improvement with employee input from those who carry out the tasks daily.

A study conducted by Forbes revealed that when Standard Operating Procedures were correctly implemented in businesses, they increased productivity by up to 70%.

Why use plain English when you can confuse everyone with acronyms? SOP in HR stands for Standard Operating Procedure, but feel free to make up your own meaning.

What Does SOP Stand for in HR?

In Human Resources (HR), the SOP acronym means Standard Operating Procedure. HR SOPs are detailed steps that organizations follow for regular and recurring tasks to ensure consistency and efficiency. These procedures outline a clear understanding of each step required, from the beginning to the end, of the task being executed. By following standard operating procedures, workplaces can anticipate problems before they occur and avoid errors.

These HR procedures help businesses establish guidelines for communicating processes and resources needed to complete operational tasks in a consistent manner. This consistency drives success with each outcome by reducing confusion about a process or service as well as gives workers an expectation of what it entails to perform assigned responsibilities.

HR SOPs must be regularly updated as work environments change over time. With recurrent evaluation, companies can develop strategic initiatives that help prevent possible ramifications of outdated documentation, safeguarding their staff and reputation.

Undoubtedly HR SOPs are crucial for any business owner who expects workplace compliance in a specific industry where certain laws or regulations apply. Having access to well-defined SOPs minimizes miscommunication within groups across organizations worldwide, ensuring timely delivery of all products and services available.

Sophisticated SOP documentation is one sure tactic for administration to reduce inefficiency through automation which directly links to financial betterment within your organization.

Why worry about SOP compliance when you can just wing it and hope for the best?

What Does SOP Stand for in Compliance?

SOP is an acronym for ‘Standard Operating Procedure’ in the context of regulatory compliance. An SOP provides a standard framework for policies and procedures to ensure that operations are carried out consistently and efficiently. Thus, ensuring that organizations are operating with the highest degree of integrity while adhering to laws and regulations.

An organization’s Compliance Standard Operating Procedures can govern different areas, including but not limited to technical procedures, human resources, or quality assurance processes. The purpose of these policies is to provide clear instructions that personnel may follow in carrying out their tasks effectively and efficiently.

An effective Standard Operating Procedure can have several benefits. It can reduce errors, eliminate confusion, reduce training time for new employees, increase efficiency, streamline processes and improve communication. To create an effective SOP, experts suggest clearly defining objectives and goals while incorporating input from professionals performing the job daily.

In summary, SOP stands for Standard Operating Procedures. These procedures serve as guidelines set up by organizations to ensure their operations run uniformly within legal and ethical boundaries while minimizing errors and promoting efficiency. Creating effective SOPs involves collaboration and defining objectives clearly with input from relevant stakeholders that understand the process requirements better than anyone else does.

Managing a project without an SOP is like trying to navigate a maze blindfolded with no map – good luck with that.

What is SOP in Project Management?

SOP, or Standard Operating Procedure, is a critical element in project management. It provides a systematic approach to ensure projects are executed effectively and efficiently. The SOP outlines the decision-making process, roles, and responsibilities of each team member involved in the project. The SOP acts as a guidebook that helps maintain consistency, mitigate risks and errors throughout the project.

An effective SOP includes all necessary steps such as planning, execution, monitoring, and closing phases of a project. It should also address how to identify potential risks or issues that may arise during the workflow and determine contingency plans to mitigate them. Having an SOP in place allows for clear communication of expectations between team members while reducing chances for miscommunication.

In specific terms, an SOP creates a policy guidebook that formalizes procedures within an organization, ensuring tasks are performed uniformly across all departments. It adds value and credibility by encouraging continuous improvement cycles as new ideas emerge.

To maximize effectiveness when implementing an appropriate SOP within your organization, delegate responsibilities clearly among project personnel. Ensure transparency by communicating important deadlines and milestones effectively amongst included departments. And the final control must always be completed comprehensively before celebrated results occur for further improvement opportunities’ sustainable execution over time.

Components of a Standard Operating Procedure

MS Word Procedure Template

Standard Operating Procedures (SOPs) are essential documents that outline the step-by-step processes and tasks required to carry out specific business operations. These documents ensure consistency, efficiency, and safety in the workplace, and are a critical component of any successful organization. Now that we’ve established the importance of SOPs, let’s take a closer look at the key components that make up these documents. While the specific format and content of an SOP may vary depending on the industry and the task at hand, there are some fundamental elements that you should include:

Purpose and Scope

Every SOP should begin with a clear statement of its purpose and scope. This section outlines why the SOP is needed and what specific processes or tasks it is designed to cover. By providing this information upfront, employees can quickly determine whether the SOP applies to their work and how it fits into the broader business context.

For instance, in a manufacturing company, an SOP might be created to outline the process of assembling a particular product. The purpose of the SOP would be to ensure that the product is assembled consistently, efficiently, and safely, while the scope would be limited to the assembly process alone.

Roles and Responsibilities

SOPs should also clearly define the roles and responsibilities of different employees or teams. This section outlines who is responsible for each step of the process and ensures that everyone understands their role in executing the SOP.

For example, in a hospital, an SOP might outline the process for administering medication to patients. The roles and responsibilities section would specify which healthcare professionals are responsible for prescribing the medication, which are responsible for administering it, and which are responsible for monitoring the patient’s response to the medication.

Procedure Steps

The heart of every SOP is the step-by-step instructions that explain how to perform a particular task or process. These steps should be detailed, easy to follow, and include any necessary safety considerations or compliance requirements.

For instance, in a restaurant, an SOP might outline the process for preparing a particular dish. The procedure steps would include the ingredients needed, the order in which they should be added, the cooking time and temperature, and any safety considerations such as how to handle sharp knives or hot surfaces.

Safety and Compliance Considerations

Speaking of safety and compliance, SOPs should also include any relevant guidelines or regulations that must be adhered to during the task or process in question. This section is particularly important in industries such as healthcare and finance, where strict regulations must be followed to ensure patient or consumer safety.

For example, in a bank, an SOP might outline the process for handling customer data. The safety and compliance considerations section would specify which regulations must be followed, such as the General Data Protection Regulation (GDPR), and how to ensure that customer data is kept secure and confidential.

Overall, SOPs are an essential tool for ensuring consistency, efficiency, and safety in the workplace. By including the key components outlined above, you can create effective SOPs that will help your organization achieve its goals and maintain high standards of quality and safety.

Benefits of Implementing SOPs in Business

Writing Standard Operating Procedures

Standard Operating Procedures (SOPs) are an essential part of any business operation. They are detailed, step-by-step instructions that outline how to complete specific tasks or processes. SOPs are designed to ensure that everyone in your organization is working towards the same goals, using the same methods, and following the same procedures.

So, what are the benefits of implementing SOPs in your business operations? Here are just a few:

Increased Efficiency and Productivity

By providing clear, step-by-step instructions, SOPs eliminate confusion and streamline processes. This can help your employees work more efficiently, reducing the time and resources required to complete tasks. With SOPs in place, your employees will know exactly what is expected of them, and they will be able to complete their work more quickly and accurately.

For example, if you run a manufacturing business, you might have an SOP for assembling a product. This SOP would outline the specific steps required to assemble the product, including the tools and materials needed, the order in which the parts should be assembled, and any quality control checks that need to be performed.

By following this SOP, your employees will be able to assemble the product quickly and efficiently, without wasting time trying to figure out what to do next.

Consistency in Operations

One of the most significant benefits of SOPs is that they promote consistency in operations. When all employees follow the same procedures every time, the results are predictable and reliable. This can improve the quality of work and reduce errors or defects.

For example, if you run a restaurant, you might have an SOP for preparing a specific dish. This SOP would outline the ingredients and quantities needed, the steps required to prepare the dish, and any plating or presentation instructions.

By following this SOP, your chefs will be able to produce the dish consistently, ensuring that every customer receives the same high-quality meal.

Improved Employee Training

SOPs also make it easier to train new employees. With a clearly defined set of procedures to follow, new hires can quickly get up to speed on how things are done in your business.

For example, if you run a retail store, you might have an SOP for opening and closing the store. This SOP would outline the steps required to turn on the lights, unlock the doors, set up the cash register, and perform any other tasks required to open or close the store.

By following this SOP, your new employees will be able to learn how to open and close the store quickly and efficiently, without needing to ask for help or guidance.

Reduced Risk of Errors and Accidents

Finally, SOPs can help to reduce the risk of errors or accidents occurring in the workplace. By providing clear guidance on safety and compliance considerations, you can help to ensure that your employees are working safely and responsibly.

For example, if you run a construction company, you might have an SOP for operating heavy machinery. This SOP would outline the safety procedures that need to be followed, including wearing appropriate safety gear, performing pre-operation checks, and following specific operating procedures.

By following this SOP, your employees will be able to operate the machinery safely, reducing the risk of accidents or injuries.

In conclusion, implementing SOPs in your business operations can have a significant impact on your efficiency, productivity, and overall success. By providing clear guidance and promoting consistency in operations, SOPs can help to ensure that your employees are working towards the same goals, using the same methods, and following the same procedures. So, if you haven’t already, consider implementing SOPs in your business today!

Developing and Implementing an Effective SOP

One of the greatest enemies in writing is clichés

Developing and implementing an effective SOP requires, identifying the need for an SOP, gathering input from stakeholders, writing an SOP, reviewing and approving the SOP, training employees on the SOP, and monitoring and updating the SOP.

Identifying the Need for an SOP

The first step in developing an SOP is to identify the need for one. This may involve observing current processes and identifying areas where more consistency or quality control is needed.

Gathering Input from Stakeholders

Once you’ve identified the need for an SOP, the next step is to gather input from relevant stakeholders. This may include employees who are currently performing the task or process, as well as managers or other stakeholders who are impacted by the outcome of the work.

Writing an SOP

With input from stakeholders in hand, you can then begin to write the SOP itself. Be sure to follow the standard format and best practices outlined earlier in this article, and take care to ensure that the document is clear, concise, and easily understandable.

Reviewing and Approving the SOP

Before rolling out the SOP to the wider team, it’s important to review and approve the document. This may involve seeking input from additional stakeholders or subject matter experts to ensure that the document is accurate and effective.

Training Employees on the SOP

Finally, you’ll need to train your employees on the new SOP. This may involve holding training sessions or providing employees with written materials to help them understand the new procedures.

Monitoring and Updating the SOP

Of course, the work doesn’t end once the SOP has been developed and implemented. It’s important to regularly monitor the document and gather feedback from employees to identify areas where improvements can be made. You should also be prepared to update the SOP as needed to ensure that it remains accurate and effective over time.

The SOP Acronym

The SOP Acronym, or Standard Operating Procedure, is a comprehensive written document that describes the workflow and activities to be taken in particular routine duties at work. Every employee is required to abide by a set of rules that provide the framework for these described principles in order to maintain efficient business operations, comply with regulations and standards, and reduce errors.

Standard Operating Procedures are a vital tool for ensuring efficiency, consistency, and compliance in business operations. By following the steps outlined in this article, you can develop and implement effective SOPs that improve the quality of work, reduce errors, and increase productivity. Whether you’re in manufacturing, healthcare, finance, or any other industry, SOPs can help to streamline your processes and drive success.

Excellent disposition