How to Find Improvement Opportunities

The first pass assessment is used to understand your metrics, flows, and constraints to flow. In the second pass assessment, we perform a more detailed analysis and produce the data for a Value Stream Map. Next, we build the analysis documents we use to communicate the issues to others. Then we need to put it all together to select improvement opportunities.

Rules for Selecting Improvement Opportunities

The rules we use for selecting improvement opportunities include:

- Look for opportunities that do not require a lot of time or money.

- Pick internal over external opportunities.

- Start with easy opportunities with high impact. (If you are new to lean and improvement then start with an easy opportunity that has a low impact in order to reduce your risk.)

The first rule is a part of Lean Thinking. If you can solve a problem by throwing a lot of resources like time and money at it, then this is not lean; it is fat thinking or thinking large.

Internal Improvement

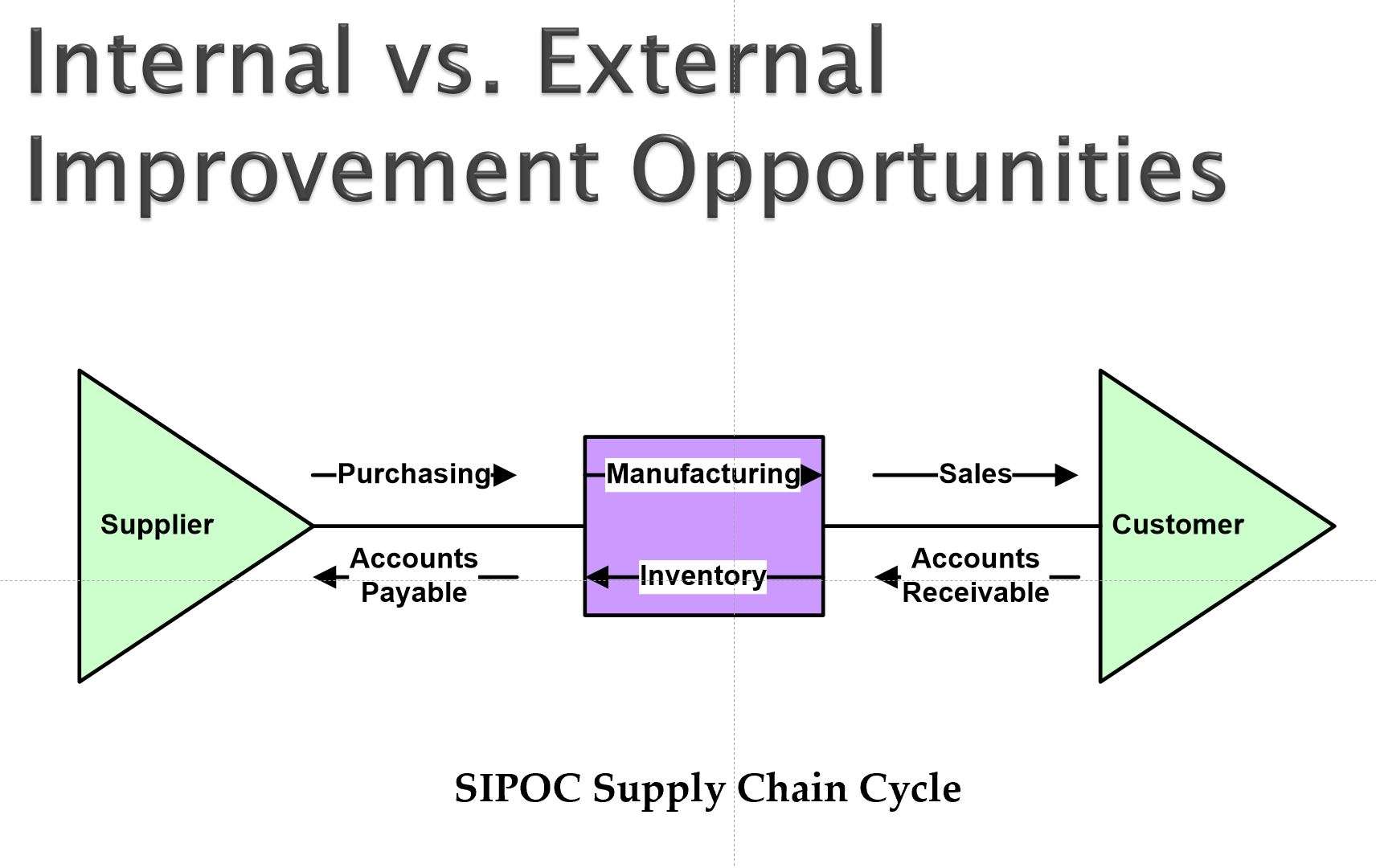

The second rule of selecting improvement opportunities is to pick internal over external opportunities. It is easier to change yourself than it is to change others. Basically, you can’t change others. Changing others is a position goal. You can set the situation up so that others can change themselves, but you can’t change them directly.

Think about it, you have more control over internal conditions like your own employees, management, and resources. Internal opportunities can happen quickly compared to external opportunities. And, internal opportunities tend to involve fewer people and locations than dealing with external opportunities composed of customers and vendors.

External Improvement

External improvement opportunities involve your customer constraints and your vendor supply chain constraints. Most companies have many customers and many different vendors. We use some of the same lean techniques in working with them. It is just that there are more entities, more employees and more managers—all in more locations. In other words, if you thought changing your internal metrics was hard, then you will understand why working on external improvements is even harder.

That is why we suggest you start on internal opportunities even when some of your biggest opportunities are external. Why? Because we need to get buy-in and to get buy-in we need success. Where will we find success? To get success we need our third rule of lean improvement: to find easy improvement opportunities.

Easy Improvement Opportunities

Easy Improvement Opportunities

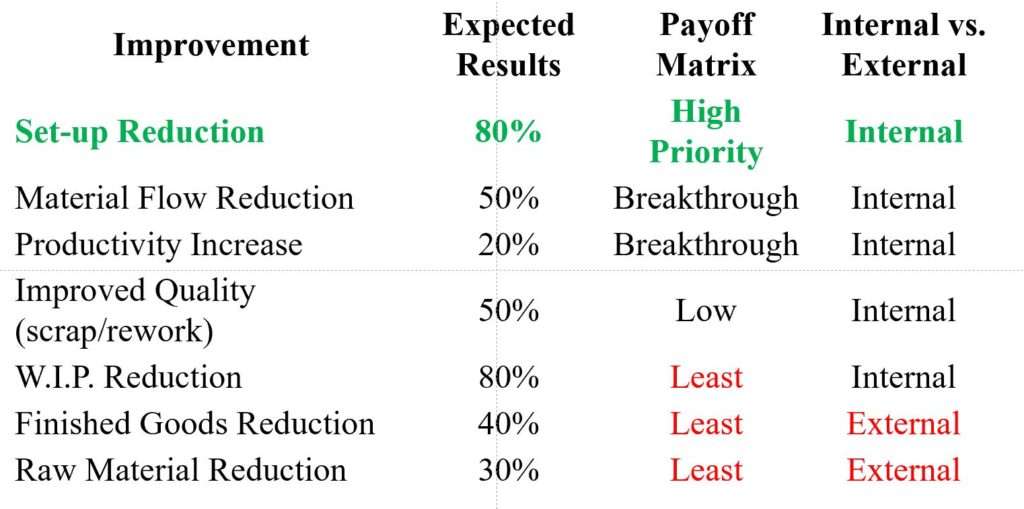

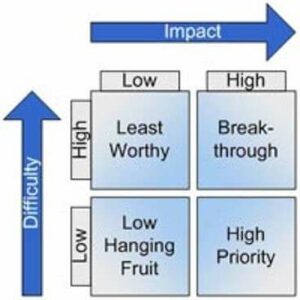

We can rank improvement opportunities by difficulty and impact using a Payoff Matrix (see figure). We are looking for easy improvement opportunities that deliver a high impact or result. If you are new to improvement and lean then I would suggest you start with opportunities that are easy and have a low impact in order to reduce your risk in the beginning.

Once you have built some success, confidence in the methods, and gotten some buy-in then you are ready to move up the matrix to your breakthrough opportunities. These will be harder but will also produce bigger results.

Do not start with the hard opportunities until you have some successes. We do not want to introduce fear.

Fear Reduces Continuous Improvement

The fear of failure kills improvement – dead. However, it is only through failure that we learn and improve. If we refuse to take risks then we maintain what we have now – status quo. Since we don’t know what we don’t know, we must take a chance and try something new to improve. We might be wrong but it is only through being wrong that we change and learn something new. So, we must celebrate mistakes and learn to seek out failure to make improvement continuous.

The goal when implementing lean thinking is to drive out fear. The first pass assessment was used to understand your metrics, flows, and constraints to flow. The second pass assessment produced a more detailed analysis and the data for creating the Value Stream Map.

Next we built the analysis documents to communicate the issues to others. Then we put it all together to select our first improvement opportunities based on our three rules of opportunity selection: (1) Look for opportunities that do not require a lot of time or money, (2) Pick internal over external opportunities, and (3) Start with easy opportunities with high impact. Now you are ready to select your first improvement opportunity.

Learn more about developing policies, procedures and processes, or improving your organization by attending the next Implementing Lean Thinking or How to create Well-Defined Processes classes.

Hi how do you evaluate improvement opportunities? can you give me an answer to this?

First you need to identify improvement opportunities. Then this article describes a few rules to select which one to work on first.