AS9100 Corrective Action Log Template Word

The AS9100 Corrective Action Log Template Word is a comprehensive tool designed to help organizations in the aviation, space, and defense industries to manage their corrective action process effectively. This template is specifically tailored to meet the requirements of the AS9100 standard, which is a widely recognized quality management system standard for the aerospace industry.

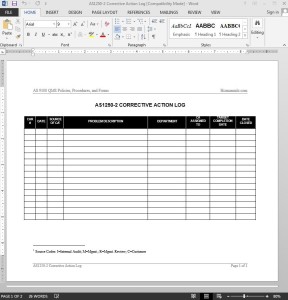

The template is easy to use and comes in a Microsoft Word format, making it easy to customize to meet your specific needs. It includes all the necessary fields to document corrective actions, including the date, description of the problem, root cause analysis, corrective action taken, and verification of effectiveness. The template also includes a section for documenting preventive actions to help prevent similar issues from occurring in the future.

Using the AS9100 Corrective Action Log Template Word can help your organization to streamline its corrective action process, reduce the risk of non-conformances, and improve overall quality. It can also help you to demonstrate compliance with the AS9100 standard during audits and inspections.

Overall, the AS9100 Corrective Action Log Template Word is an essential tool for any organization in the aviation, space, and defense industries that wants to maintain a high level of quality and compliance. With its user-friendly format and comprehensive fields, it can help you to manage your corrective action process efficiently and effectively.

>Corrective Action Log AS Template

Every Corrective Action Request (CAR) should be entered in the Corrective Action Log AS Template. The department manager should assign an employee or employees to investigate and/or take the necessary action(s) to correct and eliminate the recurrence of the problem, assign a target completion date, and notify the Quality Assurance Manager of the assignment. The Quality Assurance Manager should update AS1250-2 CORRECTIVE ACTION LOG accordingly.

The Quality Assurance Manager should maintain the status of the CAR on the Aerospace Corrective Action Log. The employee assigned to the CAR should investigate the problem within 30 days of assignment to determine the underlying (root) cause or causes. Depending on the nature of the situation under investigation, the assigned person may enlist the aid of other employees or departments to form a team to investigate and address the problem.

To effectively review the corrective action for its effectiveness, some actions may require a period of time for the action to be in place. Because of this, the Quality Assurance Manager will mark the CAR as “complete” for a period of time (i.e. 90 days) after the corrective action is taken. If the Quality Assurance Manager determines that the corrective action has been effective, they will sign and date the request form, inform the affected department manager of the “closed” status of the request, and update the AS1250-2 Log accordingly.

Corrective Action Log AS Template Details

Corrective Action Log AS Template Details

Pages: 02

Words: 26

Format: Microsoft Word 2013 (.docx)

Language: English

Manual: Aerospace

Procedure: Corrective Action Procedure AS9100 AS1250

Type: Log

Reviews

There are no reviews yet.