ISO22000 FSMS Flow Diagram Template Word

The ISO22000 FSMS Flow Diagram Template Word is a comprehensive tool designed to help businesses create a Food Safety Management System (FSMS) that meets the requirements of the ISO22000 standard. This template is perfect for food manufacturers, processors, and distributors who want to ensure that their products are safe for consumption.

The template is easy to use and comes in a Word format, making it easy to customize to your specific needs. It includes a flow diagram that outlines the steps involved in the FSMS process, from hazard analysis to monitoring and review. The template also includes detailed instructions on how to use it, making it easy for even those with little experience in FSMS to use.

Using the ISO22000 FSMS Flow Diagram Template Word can help your business achieve ISO22000 certification, which is recognized worldwide as a standard for food safety management. By implementing an FSMS, you can ensure that your products are safe for consumption, reduce the risk of foodborne illness, and improve customer satisfaction.

The template is also a valuable tool for businesses that are already certified to ISO22000. It can help you maintain your certification by providing a clear and concise overview of your FSMS process, making it easier to identify areas for improvement and ensure that your system is always up-to-date.

Overall, the ISO22000 FSMS Flow Diagram Template Word is an essential tool for any business involved in the food industry. It can help you create a comprehensive FSMS that meets the requirements of the ISO22000 standard, ensuring that your products are safe for consumption and your business is compliant with international food safety regulations.

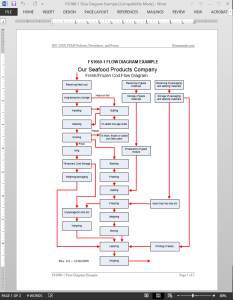

FSMS Flow Diagram Template

The Food Safety Team Leader should prepare a FSMS Flow Diagram Template for each product or process category covered by the FSMS. FS1060-1 FLOW DIAGRAM EXAMPLE is a sample flow diagram for a seafood products company, showing the process steps in order. Flow diagrams provide a basis for evaluating any possible occurrence, increase, or introduction of food safety hazards. Flow diagrams should be clear, accurate, and sufficiently detailed and should include the following, as appropriate:

- The sequence and interaction of all steps in the operation;

- Any outsourced processes and subcontracted work;

- Where raw materials, ingredients, and intermediate products enter the flow;

- Where rework and recycling take place; and

- Where end products, intermediate products, by-products, and waste are released or removed.

Hazard analysis is the process of collecting and evaluating information on hazards associated with a food ingredient/product, to determine which hazards are significant and must be addressed in the HACCP plan. Hazard analysis consists of two steps, identification and evaluation. By ensuring accurate, thorough, and effective hazard analyses, the company is better able to guarantee the safety and efficacy of food products and/or ingredients under its control and ensure that its products conform to customer and statutory/regulatory requirements.

FSMS Flow Diagram Template Details

FSMS Flow Diagram Template Details

Pages: 02

Words: 92

Format: Microsoft Word 2013 (.docx)

Language: English

Manual: ISO 22000

Procedure: FSMS Hazard Analysis Preparation Procedure FDS1060

Type: Guide

Reviews

There are no reviews yet.