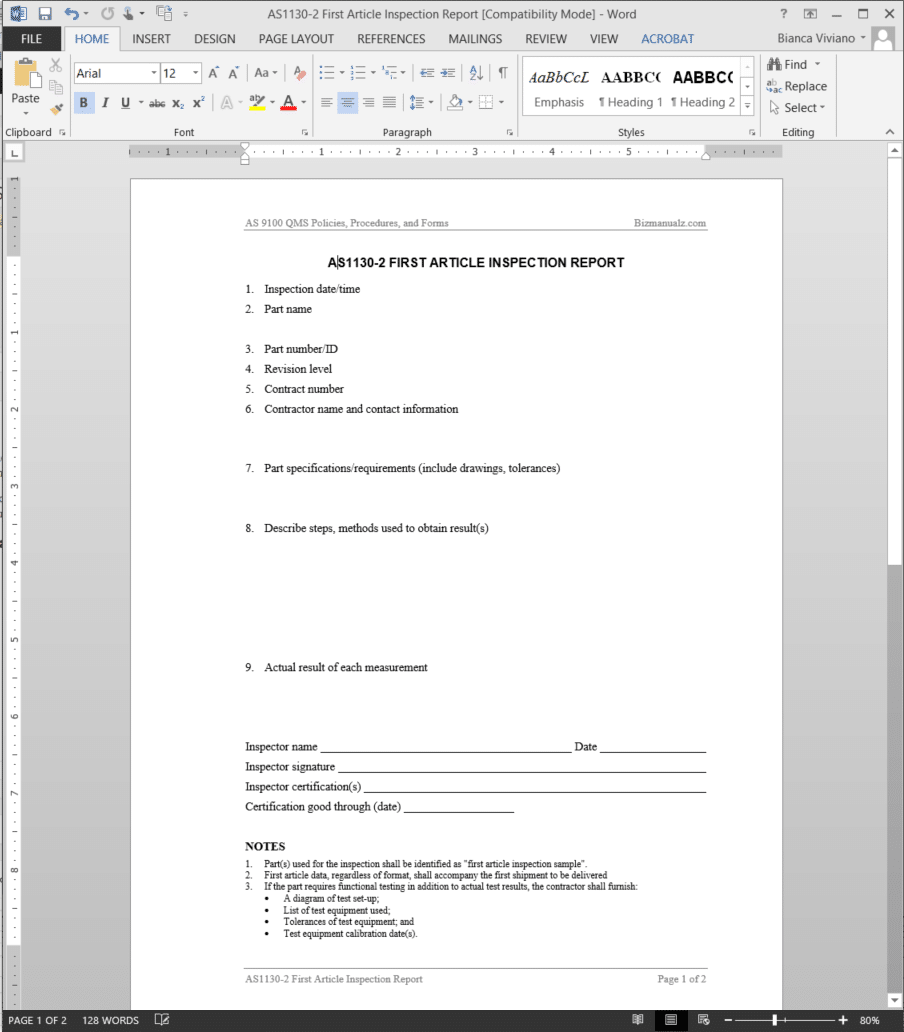

AS9100 First Article Inspection Report Template Word

The AS9100 First Article Inspection Report Template Word is a comprehensive and easy-to-use tool that helps aerospace and defense manufacturers comply with the AS9100 standard. This template is designed to assist manufacturers in creating a detailed report that documents the results of the first article inspection process.

The AS9100 First Article Inspection Report Template Word includes all the necessary sections required by the AS9100 standard, such as part identification, drawing and specification references, inspection results, and non-conformance reports. The template also includes a section for documenting corrective actions taken to address any non-conformances found during the inspection process.

Using this template can save manufacturers time and effort in creating a first article inspection report that meets the AS9100 standard. The template is fully customizable, allowing manufacturers to tailor it to their specific needs and requirements. It is also easy to use, with clear instructions and guidance provided throughout the document.

The AS9100 First Article Inspection Report Template Word is a valuable tool for aerospace and defense manufacturers who want to ensure compliance with the AS9100 standard and maintain the highest levels of quality in their products. By using this template, manufacturers can streamline their first article inspection process and improve their overall quality management system.

First Article Inspection Report AS Template

A First Article Inspection Report AS Template may be required on some items (e.g., new parts, part revisions). If the company requires an Aerospace First Article Inspection Report, the Quality Assurance Manager should verify that the supplier’s FAI report addresses the company’s requirements using the AS1130-2 FIRST ARTICLE INSPECTION REPORT as a guide. If multiple part numbers are included in a shipment, each part will be segregated and handled (e.g., inspected, put into stock) according to applicable requirements.

The Quality Assurance Manager should periodically pull samples of incoming parts, components, materials, etc., to verify that the items conform to requirements and validate suppliers’ test reports and certifications. The Quality Assurance Manager is responsible for conducting detailed examinations of incoming materials, when necessary, and for recommending acceptance or rejection of goods to the Procurement Manager.

First Article Inspection Report AS Template Details

First Article Inspection Report AS Template Details

Pages: 02

Words: 128

Format: Microsoft Word 2013 (.docx)

Language: English

Manual: Aerospace

Procedure: Receiving Inspection Procedure AS9100 AS1130

Type: Report

Reviews

There are no reviews yet.