How To Eliminate Process Delays?

Delays, we all encounter them everyday. But process delays are one of the biggest causes of ineffectiveness, inefficiencies, and poor performance.

Do you realize that if you could reduce or eliminate delays by 50%, you could reduce the fluctuations in your processes by as much as 80%? Therefore finding and eliminating process delays is a primary objective for process improvement.

What Is a Delay?

Webster’s dictionary defines a delay as: to stop, detain, or hinder for a time; to move or act slowly; to cause to be late or behind in movement or progress. Synonyms include: retard, slow, slacken, detain, put off, and postpone. As you can see, none of these are particularly flattering terms for your process.

How Do You Eliminate Process Delays?

How Do You Eliminate Process Delays?

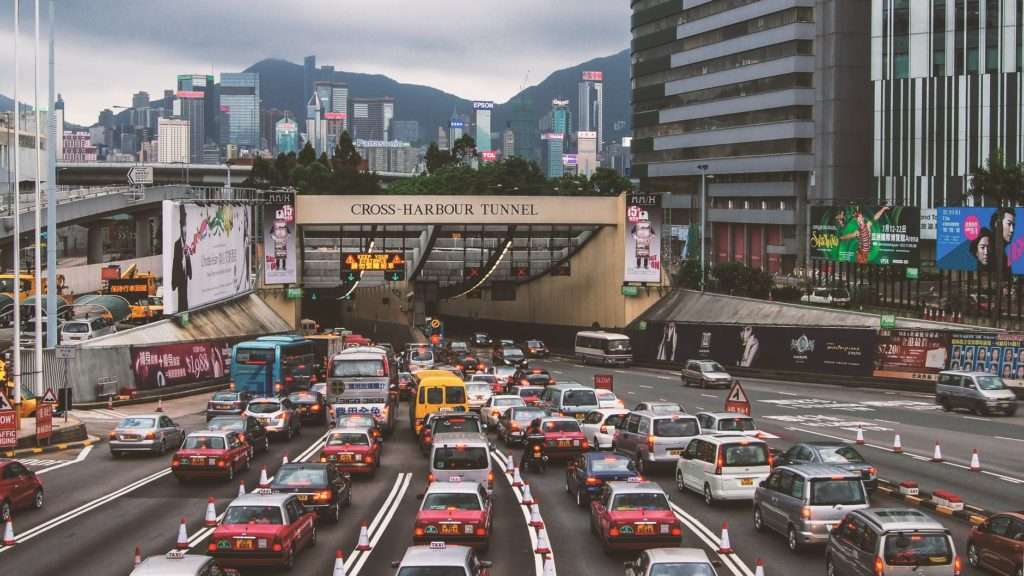

Most delays occur at transition points (handoffs) from one process step to another. By reducing the number of transitions or process steps we can significantly reduce process delays. Research has shown that providing equal capacity at all steps within the process is the best way to eliminate delays. Adding flexible capacity for potential changes in demand at only one step will lead to increasing delays downstream later in the process. Thus you should make every effort to design in equal capacity at all steps within your processes to eliminate delays.

How Do Bottlenecks Compare to Delays?

A bottleneck is a type of delay where a process step has less capacity at its input than is demanded. As such, it determines the overall velocity or speed of the whole process. Any changes made to improve individual steps of a process, without addressing the bottleneck, are likely to fail to improve the process at all.

Start by analyzing the process using a process map to identify your bottlenecks and delays. The aim is to identify where the flow slows within the process. Note that the bottleneck is not necessarily the step with the largest queue. Bottlenecks frequently occur when many sources merge into a single narrow channel.

What Can You Do About Process Bottlenecks?

- Ensure that the bottleneck has no idle time

- Put inspection or checking tasks in front of the bottleneck

- Distribute the work amongst non-bottleneck areas, even if it is less “efficient”

- Having improved the situation at one bottleneck it is likely that others will emerge as rate-limiting steps

What Else Can You Do About Delays?

As odd as it seams, you could do nothing. Many times when we act to fix something we don’t see any immediate results and we don’t realize that there is a delay, so we continue to take actions. Doing something makes us feel like we are in control. But doing something, without understanding the delay, can lead to overcorrection. Now your process results are zig-zagging. Therefore, it’s critical to understand your process delays, when to take action and when to just do nothing.

When in doubt, focus on understanding the process first before changing it. After all, if you spend less time changing things that don’t change the overall system’s performance, then you will have more time to change the things that do improve performance. In other words, think more, do less, achieve more.

The System Produces the Results

The outcomes you receive from a process come from the design of the process. One major cause of poor process performance (waste) is delay. So we want to eliminate process delays the best we can but, first you must understand the delays before making any changes (quantitatively measure them). If delays are caused by bottlenecks then optimize the process (redesign) for bottleneck. You now have a step-by-step method for improving your processes in a continuous manner.

[…] prepare a replacement or work around it. If your team is unable to communicate effectively, it will lead to delays, disputes and other problems that are going to slow down your […]