What Does Quality Planning Mean?

Quality planning is how we plan to make a product (or deliver a service) correctly. Think of it as planning to make the perfect product (or deliver the perfect service) experience for your customer. Ah, the perfect order, from the perfect customer… But what does Quality Planning mean?

Quality Planning: The Perfect Product Experience

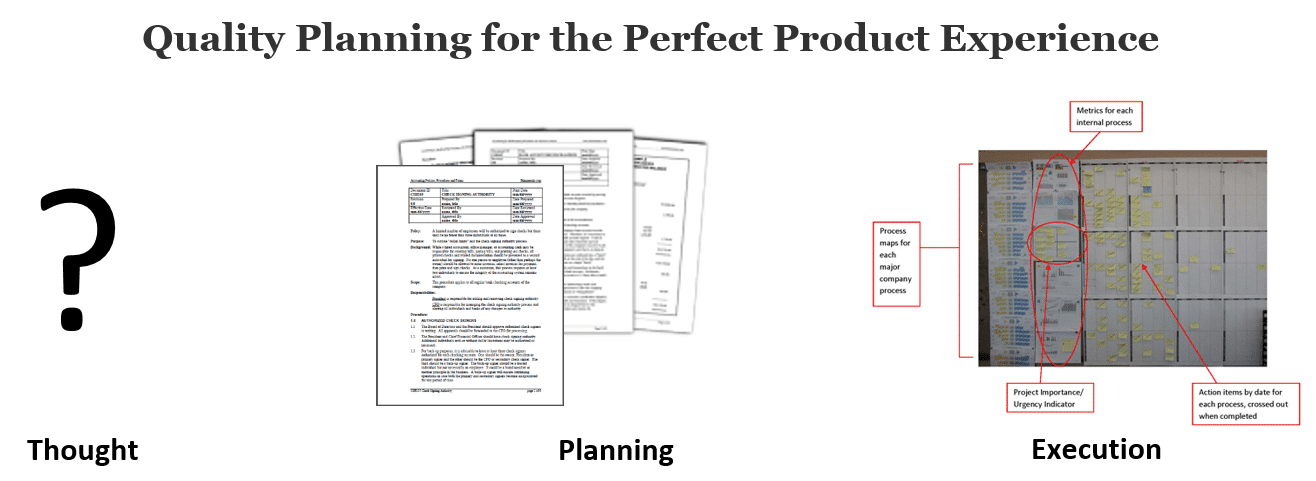

Quality planning is about creating the perfect product experience, but perfection doesn’t happen by accident. Perfection is not random. The quality planning process takes careful thought, planning, and execution. Each element has an important role in working towards perfection – or as we think of it in quality as the elusive zero defects goal.

Defining the Product Experience

Careful thought means keeping the voice of the customer in mind as your think through all the requirements, resource needs, transaction steps, and analyzing all of the risks in what can go wrong. Then defining what the product experience really is you are trying to create for your customers.

Planning the Product Experience

Planning means creating the quality controls to ensure the perfect product is made, perfectly. Quality controls include developing the policies, procedures, work instructions, forms, metrics, measuring devices, dashboards, etc.

There are many documents that help writing policies, procedures, and quality control plans. These countermeasures are the details that make up the day-to-day risk management process to ensure we are working towards the perfect product experience and there are no surprises.

Realizing the Product Experience

Execution means developing the discipline necessary to consistently follow the quality controls that you spent so much time developing in order to make the perfect product experience for your customer. For most people, this is the hardest part.

Did you plan for everything that can go wrong? Probably not. That is why we have internal auditing, corrective action, and root cause analysis so we can adjust to the dynamics of the real world.

Planning Policies and Procedures

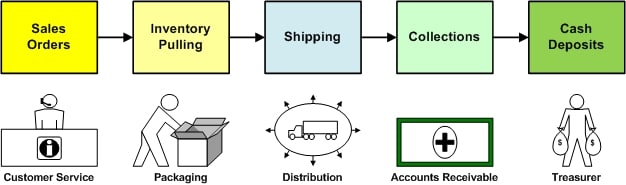

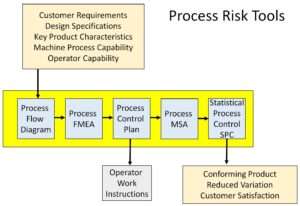

To make a perfect part, one has to first plan the sequence of production or service steps. A process flow diagram or process map is used to define the total number of steps. These might include sales order acceptance, purchasing raw materials, receiving raw materials, and each individual production step (i.e. cutting, welding, assembly, painting, inspection, and delivery).

The Revenue Process Map below depicts a simple five step process for a distributor. Sales takes the order, the product is pulled from inventory, shipping delivers product, accounting collects the receivables, and cash deposits are reconciled to complete the cycle.

Once each step is defined, we can now analyze the requirements, determine what can go wrong, and develop the controls and countermeasures to ensure our employees are doing it right. Only then, are we really ready to write policies and procedures that define the product experience our employees are working towards.

Example process failures include:

- Sales can enter the order incorrectly, enter it late, fail to clarify part details, fail to ask for up selling or cross-selling items, etc.

- Inventory can pull the wrong part, damaged parts, only part of the order, the part could be back-ordered, etc.

- Distribution or shipping could package it incorrectly, it could be damaged in transit, sent via the wrong carrier or shipping class, etc.

- Accounts Receivable could fail to collect, collect on-time, apply the receipts to the wrong account, etc.

- Treasurer could fail to deposit receipts in a timely manner, deposit to the wrong account, reconcile the account, etc.

Plus there is always the opportunity for fraud, embezzlement, theft, and other forms of waste that should be accounted for also.

Writing Policies and Procedures

Writing policies and procedures is a lot easier after the first step of defining the product experience we want and how our employees are supposed to create that product experience. Often times people look at a blank page and ask, “What do you want me to write?”

After we have the product experience defined in some detail, along with what can go wrong, then answering this question of how to write policies and procedures is actually quite easy. Starting with policy and procedure templates makes it even easier because many processes are very similar in design yet vary somewhat in the details.

Using Policies and Procedures

When you use our online document management system, procedures, records, and rights to use or edit them are managed within the web-based system. Deployment — and control — become very easy.

For most people, using policies and procedures is the hard part. In order to truly realize your product experience vision you will have to get the execution right. Procedure Software helps to ensure people are accessing the right document versions, using approved procedures, and following the procedures you want them to use.

Of course this is all easier with the first two steps completed correctly. A clear understanding of the product experience coupled with a clear set of product experience controls will make realizing the product experience much easier.

Quality Planning: the Perfect Product Experience

Nobody’s perfect, but by using a quality planning system of thinking about the product experience, planning for that perfect product experience and then focusing everyday on delivering the best product experience the customer can expect, then we are truly doing the best we can.

Your policies and procedures are critical controls used in the realization of the perfect product experience. To learn more about Bizmanualz policies and procedures, download free policies and procedures right now.